ENGINE

DISASSEMBLY AND ASSEMBLY

TM 5-3805-263-14&P-2

FLYWHEEL HOUSING

REMOVE FLYWHEEL HOUSING

Tools Needed

A

FT121

Lifting Bracket

1

S509

Bolt

1

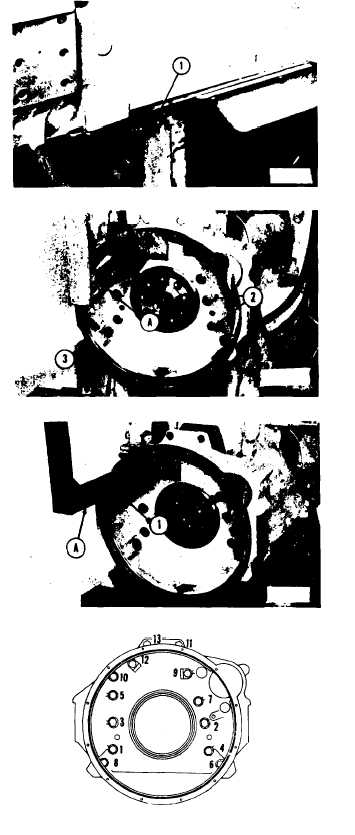

1.

2.

3.

4.

start by:

a) remove flywheel

b) remove starting motor

Loosen the bolts that hold the oil pan and oil pan

plate to the cylinder block. Remove the bolts that

hold the oil pan plate to the flywheel housing.

Fasten a hoist to the rear of the engine. Lift the

rear of the engine and install shims (1) on each

side of the engine between the cylinder block and

oil pan plate.

Install tooling (A) on the flywheel housing. Re-

move bolts (2) that hold the flywheel housing to

the cylinder block.

Remove flywheel housing (3) from the engine.

The weight of the flywheel housing is 85 lb. (39

kg).

INSTALL FLYWHEEL HOUSING

Tools Needed

A

FT121

Lifting Bracket

1

S509

Bolt

1

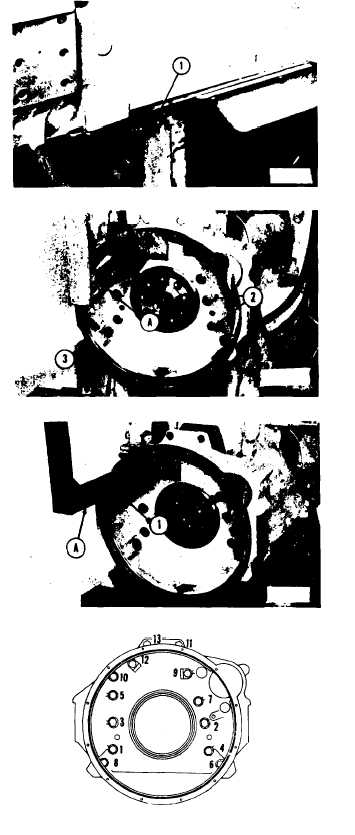

1.

2.

3.

Clean the old gasket from the surfaces of the

cylinder block and flywheel housing that make

contact with each other. Install a new gasket on

the cylinder block.

Install two ½" - 13 NC guide bolts (1) in the

cylinder block as shown. Install tooling (A) on

the flywheel housing. Fasten a hoist and put the

flywheel housing in position on the guide bolts.

Install all but two bolts in the flywheel housing.

Remove tooling (A) and guide bolts. Install the

other two bolts. Tighten the flywheel housing

bolts in the sequence as shown in illustration.

Cut the bottom of the gasket even with the fly-

wheel housing and cylinder block. Put 5H2471

Gasket Cement on the bottom of the gasket

where the gasket makes contact with the gasket

for the oil pan plate. Remove shims from each

side of the engine. Tighten all of the oil pan bolts.

Install the bolts that hold the oil pan plate to the

flywheel housing.

end by:

a) install electric starting motor

b) install flywheel

1-214