FUEL SYSTEM

SYSTEMS OPERATION

TM 5-3805-263-14&P-2

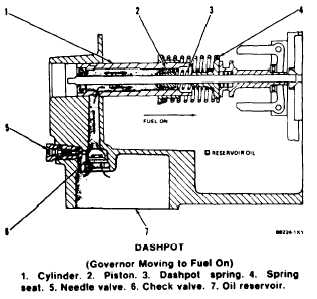

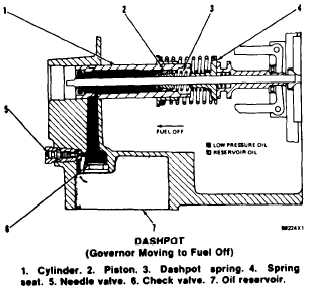

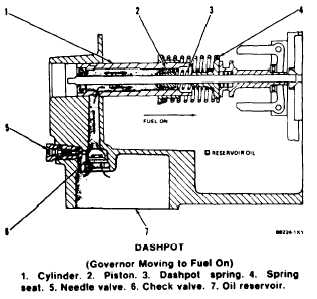

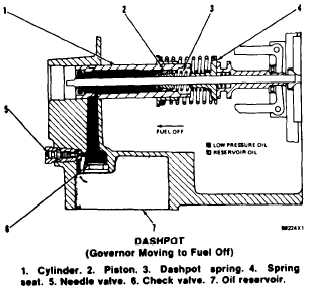

changes. The dashpot has cylinder (1), piston (2).

dashpot spring (3), needle valve (5) and check valve

(6). Piston (2) and spring seat (4) are fastened to

dashpot spring (3).

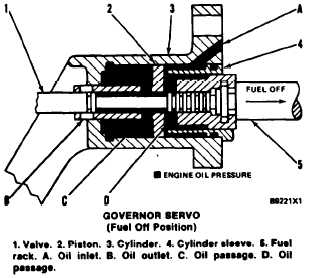

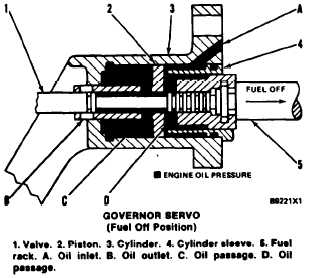

When the governor spring and flyweight forces are

balanced and the engine speed is constant, valve (1)

stops moving. Pressure oil from oil inlet (A) pushes

piston (2) until oil passages (C and D) are opened.

Oil now flows through oil passage (D) along valve (1)

and out through oil outlet (B). With no oil pressure

on the piston. the piston and fuel rack (5) stop

moving.

When the governor moves in the FUEL OFF dir-

ection, valve (1) moves to the right. The valve closes

oil outlet (B) and opens oil passage (D). Pressure oil

from oil inlet (A) is now on both sides of piston (2).

The area of the piston is greater on the left side than

on the right side of the piston. The force of the oil is

also greater on the left side of the piston and moves

the piston and fuel rack (5) to the right.

Dashpot

The dashpot helps give the governor better speed

control when there are sudden speed and load

When the governor moves toward FUEL ON,

spring seat (4) and piston (2) move to the right. This

movement pulls oil from oil reservoir (7) through

check valve (6) and into cylinder (1).

When the governor moves toward FUEL OFF,

spring seat (4) and piston (2) move to the left. This

movement pushes oil out of cylinder (1). through

needle valve (5) and into oil reservoir (7).

If the governor movement is slow. the oil gives no

restriction to the movement of the piston and spring

seat. If the governor movement is fast in the FUEL

OFF direction, the needle valve gives a restriction to

the oil and the piston and spring seat will move

slowly.

1-11