TM 5-3805-261-23-2

WHEEL SPINDLE, BEARINGS, AND SEALS REPLACEMENT - CONTINUED

0302 00

INSTALLATION - CONTINUED

8.

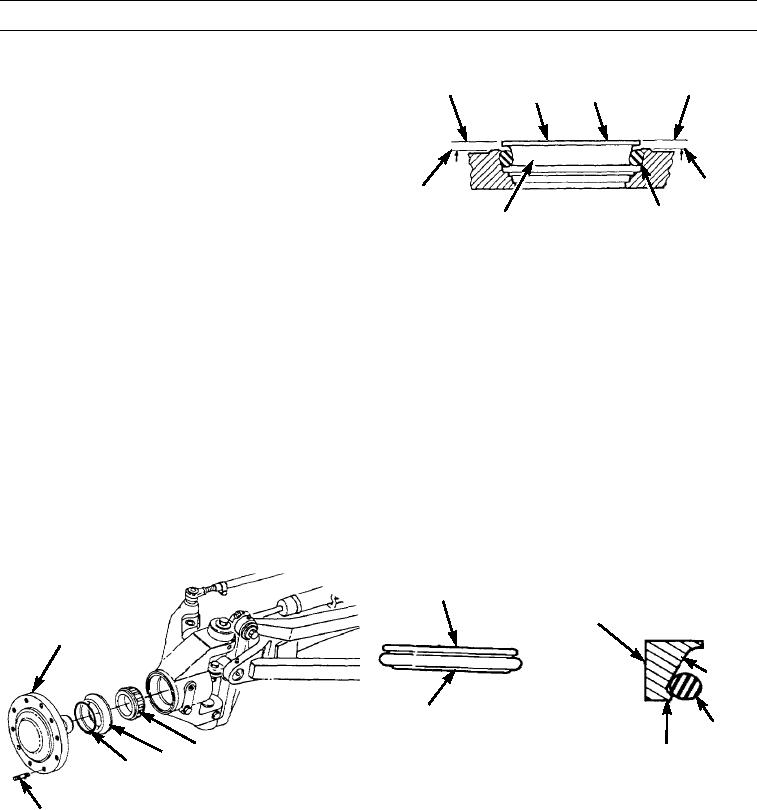

Measure at points (A through D), 90 degrees apart

B

A

20

D

with depth rule gauge. Check height from housing

surface to top of seal (20). Differences in heights

between points (A through D) must not exceed 0.04 in

(1.0 mm).

HOUSING

HOUSING

SURFACE

19

SURFACE

C

397-4186

9.

Adjust seal (20) and ring (19), if necessary, using a seal inserter.

NOTE

If any dirt particles remain on seal face, seal will leak.

10.

Clean seal (20) mating surface with a lint free cloth.

11.

Lubricate mating surface of seal (20) with gear lubricant.

12.

Inspect ring (19) for twists or bulges. Incorrect installation will result in seal (20) failure. If incorrect installation is obvi-

ous, repeat steps 6 through 11.

13.

Install 10 studs (15) on spindle (11). Tighten studs to 170 lb-ft (230 Nm).

14.

Install bearing (12) on spindle (11).

15.

Install ring (14) on seal (13). Ensure ring is not twisted and is seated properly on bottom of seal ramp and against retain-

ing lip.

13

20

11

RAMP

14

19

12

RETAINING LIP

13

14

397-4183

397-4181

15

0302 00-5