TM 5-3805-261-23-1

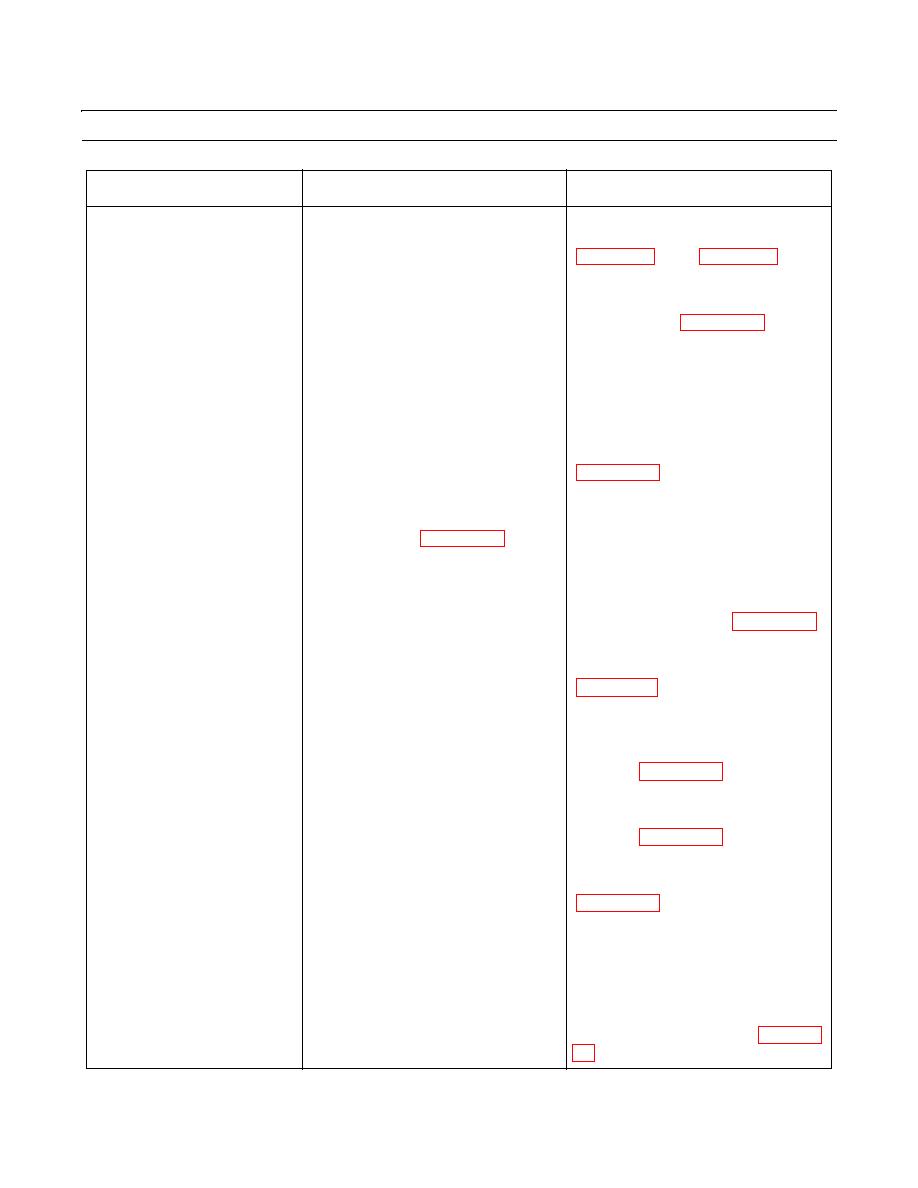

HYDRAULIC SYSTEM TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

Check the hydraulic hoses for leaks

If a hydraulic hose fitting is loose, tighten.

1.

All Implements Fail to

and loose fittings.

Operate or Operate

If a hose is damaged or defective, replace

Slowly.

problem still exists, go to Test 2.

2.

Check the hydraulic filters.

If the filters are clogged, damaged, or

defective, replace (WP 0231 00). If the

problem still exists, go to Test 3.

3.

Check the hydraulic pump assembly.

If the hydraulic pump assembly is

damaged or defective, replace (WP 0329

00).

1.

Check the circle drive hydraulic

If a circle drive fitting is loose, tighten. If

2.

Circle Drive Operates

hoses for leaks and loose fittings.

Slowly or Fails to Operate.

hose is damaged or defective, replace

go to Test 2.

2.

Check hydraulic system pressures at

If the problem still exists, go to Test 3.

control valve (WP 0237 00).

3.

Measure circle drive operation time.

The time for one quarter revolution in

Using a stop watch, measure the

either direction is 9.5 to 11.5 seconds. If

amount of time for one quarter

the time recorded is not within the range,

revolution.

replace circle drive motor (WP 0217 00).

1.

Check the blade float hydraulic hoses

If a blade float fitting is loose, tighten. If

3.

Blade Float Fails to

for leaks and loose fittings.

Operate Properly (CCE

a hose is damaged or defective, replace

Machine).

go to Test 2.

2.

Check to see if it is one or both sides

1.

If both sides of the blade float do not

of the blade that do not float.

operate, replace blade float pilot

valve (WP 0233 00).

2.

If one side of the blade float does not

operate, replace blade float check

valve (WP 0234 00).

1.

Check the blade lift hydraulic hoses

If a blade lift fitting is loose, tighten. If a

4.

Blade Lift Fails to Operate

for leaks and loose fittings.

Properly.

hose is damaged or defective, replace

go to Test 2.

2.

Measure blade lift time. Using a stop

The time for the blade to be lifted is 0.5 to

watch, measure the amount of time

9.5 seconds. If the time is not within

for the blade to be listed from the

range, replace hydraulic pump (WP 0329

ground to the stopping point.

00). If the problem still exists, go to Test 3.

3.

Check blade lift cylinder for leaks

Replace if leaking or damaged (WP 0245

and damage.