TM 5-3805-261-20

HYDRAULIC SYSTEM MAINTENANCE. (cont)

15-6.

Blade Float Check Valve. (Sheet 2 of 3)

REMOVAL

NOTE

•

All hose and tube assemblies must

be tagged before disconnecting to

aid in installation. Cap all hose and

tube ends to prevent contamination.

•

The following is a maintenance

procedure for the left side blade float

check valve. The maintenance

procedure for the right side blade

float check valve is identical.

1.

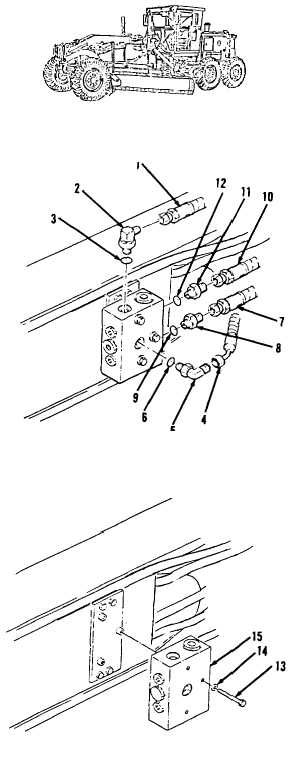

Disconnect hose assembly (1, Figure 15-4).

2.

Remove elbow (2) and preformed packing

(3). Discard preformed packing (3).

3.

Disconnect hose assembly (4).

4.

Remove elbow (5) and preformed packing

(6). Discard preformed packing (6).

5.

Disconnect hose assembly (7).

6.

Remove connector (8) and preformed

packing (9). Discard preformed packing

(9).

7.

Disconnect hose assembly (10).

8.

Remove connector (11) and preformed

packing (12). Discard preformed packing

(12).

9.

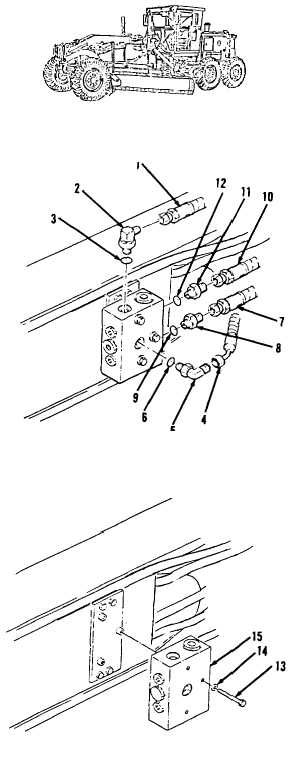

Remove three bolts (13) and washers (14,

Figure 15-15).

10.

Remove blade float check valve (15).

Figure 15-5.

Go to Sheet 3

15-16

Figure 15-4.