TM 5-3805-293-23-3

0044

HYDRAULIC CYLINDER DRIFT CHECK

00044

WARN I N G

Hydraulic oil pressure can remain in the hydraulic system on this machine after the engine

and pump have been stopped. Serious injury can result if this pressure is not released

before any service is done on the hydraulic system. In order to prevent possible injury,

release the hydraulic system pressure before working on any fitting, hose, or hydraulic

component.

Hydraulic cylinder drift is anymovement of the cylinder rod, when the cylinder rod is in the

HOLD position. During normal operation, movement of the cylinder can affect the

performance of the machine.

Any of the following examples may cause cylinder drift:

The cylinder piston seal is damaged.

A scratch in the cylinder bore or a groove in the cylinder bore.

A scratch on the cylinder rod ora groove on the cylinder rod.

The cylinder head seal is damaged.

Dirt in the lock valve or the lock valveis damaged in the implement control valve.

Loose fittings or damaged hydraulic lines that have oil leaks.

Dirt in the line relief valves or the line relief valves are damaged.

1. To test for cylinder drift, perform the following operation:

a. Start machine (TM 5-3805-293-10).

b. The hydraulic oil temperature should be 100 to 122F (38 to 50C).

c.

Extend the blade lift cylinder rod halfway and put the cylinder rod in the HOLD position (TM 5-3805-293-

10).

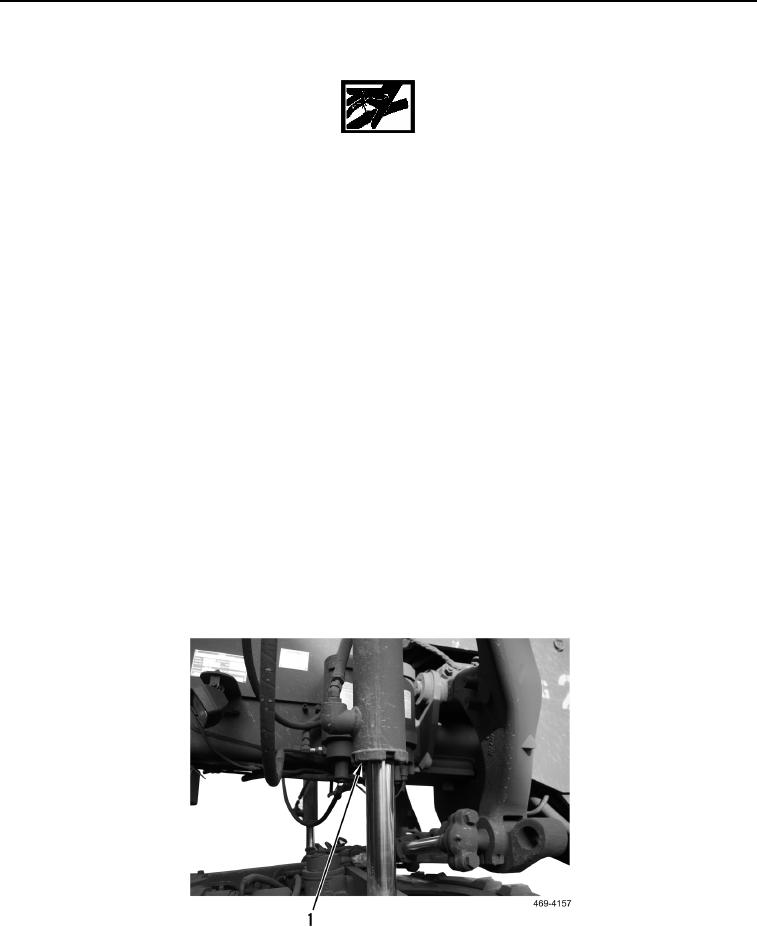

d. Mark cylinder position (Figure 126, Item 1).

Figure 126. Mark Cylinder Position.

0044