TM 5-3805-293-10

0013

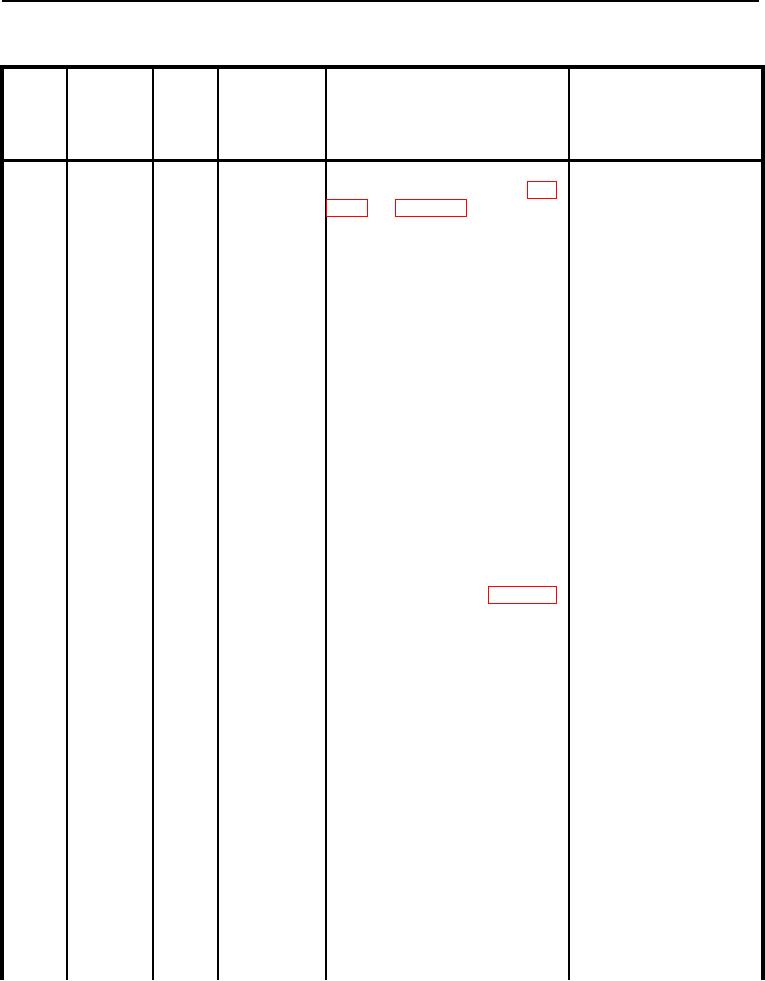

Table 1. Preventive Maintenance Checks and Services (PMCS)

with Lubrication Information - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NOT FULLY MISSION

NO.

INTERVAL HOURS

SERVICE

PROCEDURE

CAPABLE IF:

Damage that would impair

49

After

Scarifier

Check scarifier frame, link sockets,

operation, or missing six

and teeth for excessive wear (WP

scarifier teeth if required for

mission.

missing components.

50

After

Hydraulic

a. Check scarifier hydraulic

Class III leaks or damage

that would impair operation.

Cylinders

cylinder and hoses for damage or

leaks.

b. Check left blade lift cylinder and Class III leaks or damage

that would impair operation.

hoses for damage or leaks.

c. Check centershift cylinder and

Class III leaks or damage

that would impair operation.

hoses for damage or leaks.

51

After

Circle Drive

Check all circle drive and circle

Class III leaks or damage

that would impair operation.

drive components for leaks,

damage or debris. Remove debris.

52

After

Blade, Cutting a. Check entire blade for damage

Damage or distortion.

Edges, and

or distortion.

End Bits

b. Check all cutting edges and end Damage or loose bolts.

bits for damage or loose bolts.

c. Check all cutting edges and end Cutting edge or end bits are

bits for excessive wear (WP 0019). worn to within 3/4 in.

(19 mm) of blade.

d. Check sideshift cylinder for

Class III leaks or damage

debris, damage, or leaks. Remove that would impair operation.

debris.

53

After

Blade Work

Ensure blade work lights are

Missing or damaged

Lights

present and securely mounted.

components if necessary

for mission.

54

After

Left Door

Check left door for damage or

Missing or damaged

missing components.

components if necessary

for mission.

55

After

Left Mirror and Check left side mirror and step for

Missing or damaged

Step

damage or missing components.

components if necessary

for mission.

56

After

Rollover

Check ROPS for damage and

Loose or missing ROPS

Protective

loose or missing mounting bolts.

bolts or damage to

Structure

structure.

(ROPS)

0013-21