FUEL SYSTEM

TM 5-3805-263-14&P-2

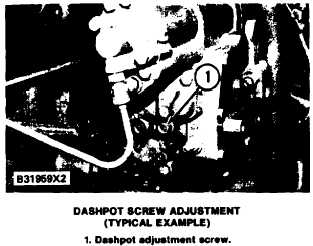

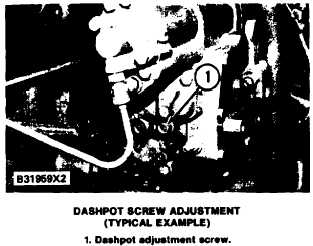

1. Turn dashpot adjustment screw (1) in (clock-

wise) until it stops.

2. Turn dashpot adjustment screw out (counter-

clockwise) 1/2 ± 1/4 turn.

Checking Balance Point

The balance point for the engine is:

1. At 20 rpm higher than full load speed.

2. The point where the power adjustment screw is

against the load stop.

3. The point where the engine has the most horse-

power output.

4. The point where an increase in load on the engine

puts the engine in a lug condition (a condition in

which a small increase in load makes the engine

speed get much less).

Procedure for Checking Balance Point

NOTE: It is important,

to the correct operation of

the transmission, that the BALANCE POINT is

adjusted to the correct specifications.

NOTE: The rack setting must be correct before

an adjustment is made to the balance point.

I. Connect a tachometer which has good accuracy

to the tachometer drive.

TESTING AND ADJUSTING

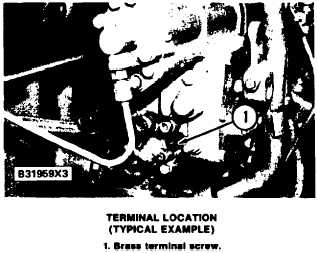

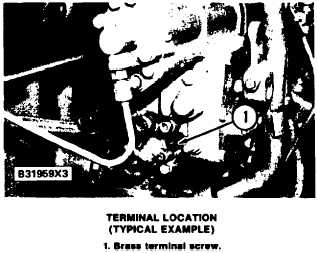

2. Connect a continuity light to the brass terminal

screw (1) on the rear of the governor. Connect

the other end of the light to a place on the fuel

system which is a good electrical ground.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Start the engine.

With the engine at operating conditions, run the

engine at high idle.

Make a record of the speed of the engine at high

idle.

Add load on the engine slowly until the contin-

uity light just comes on. This is the balance

point.

Make a record of the speed at the balance point.

Repeat Step 6 several times to make sure that

the recording is correct.

Stop engine. Make a comparison of the records

from Steps 5 and 7 with the information given

in the FUEL SETTING INFORMATION.

If the full load speed is not correct, adjust the

HIGH IDLE speed to make a change in the full

load speed.

If the high idle speed is out of tolerance and the

full load speed is correct, look for a weak gover-

nor spring or the wrong governor spring. Both

the full load speed and the high idle speed must

be in the tolerance given in the FUEL SET-

TING INFORMATION.

1-56