FUEL SYSTEM

TESTING AND ADJUSTING

The TIMING CHART gives the acceptable dyn-

amic (engine in motion) timing range as read on the

Timing Indicator Group. The TIMING CHART is

for the 3304 Engine with 20 ± 1° static (engine

stopped) timing.

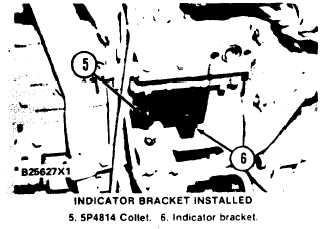

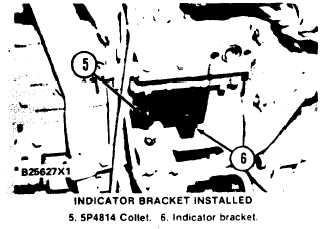

3. Install 5P4814 Collet (5) on indicator bracket

(6).

TIMING CHART

ENGINE rpm

INDICATOR READING

700

19.5 to 21.9°

2300

21.1 to 23.5°

If the engine timing is not correct. make reference

to CHECKING TIMING BY TIMING PIN

METHOD for the procedure to change engine

timing.

RACK SETTING PROCEDURE

Tools Needed:

7N1048 Timing Pin.

6V2106 Rack Adjustment Tool Group.

6V2128 Compressor, Over fueling spring.

6V2031 Rack Position Indicator.

9S229 Contact Point 9.7 mm (.38 in.) long.

5P4814 Collet.

6V3075 Dial Indicator.

8S4627 Circuit Tester.

The rack setting can be done with the fuel injection

pump and governor on or off the engine.

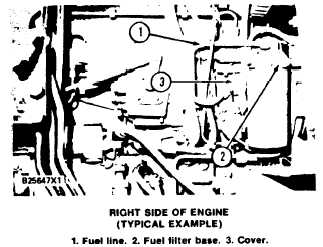

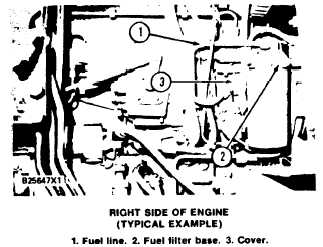

1. Remove fuel line (1) and fuel filter base (2)

and filter from the furl injection housing.

2. Remove cover (3) from the side of fuel in-

jection housing.

TM 5-3805-263-14&P-2

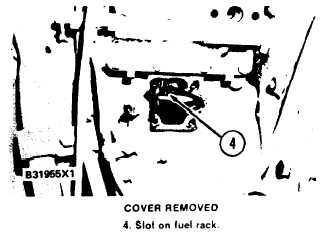

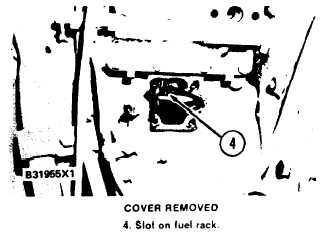

4. Install indicator bracket on the fuel pump

housing. The lever on the bracket assembly

must be in slot (4) on the fuel rack. After the

bracket assembly is tightened to the housing.

the lever must move smoothly when the gover-

nor is moved from low idle to high idle.

1-51