FUEL SYSTEM

TESTING AND ADJUSTING

TM 5-3805-263-14&P-2

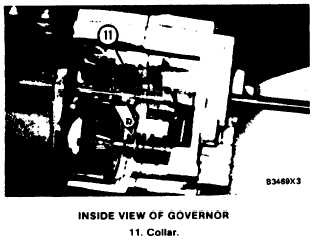

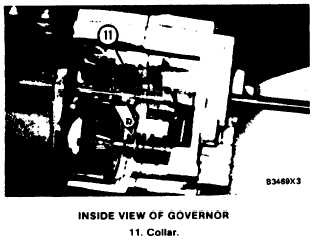

NOTE: The 6V2128 Compressor is used to com-

press the over fueling spring. The over fueling

spring must be compressed to get an accurate fuel

rack measurement. When the compressor is in-

stalled. the end of the compressor contacts and

moves collar (I I) in the governor.

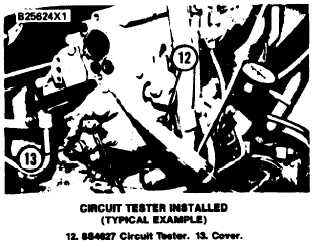

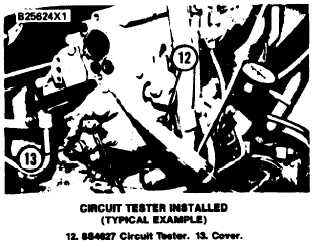

10. Fasten the clip end of 8S4627 Circuit Tester

(12) to the rack contact on the rear of the gov-

ernor housing and put the other end to a good

electrical ground.

11.

12.

13.

Hold the governor lever in the FUEL ON

position. Turn the bolt in compressor (10) in

(clockwise) as far as it will go. This removes

the free play inside the governor.

Now turn the bolt out (counterclockwise)

until the light just comes on (dim light). This

is the static fuel setting. Make reference to

the FUEL SETTING INFORMATION for

the correct static fuel setting. and compare

with the reading on the dial indicator.

If the static fuel setting is not correct. remove

lockwire and seal. and cover (13) from the rear

of the governor.

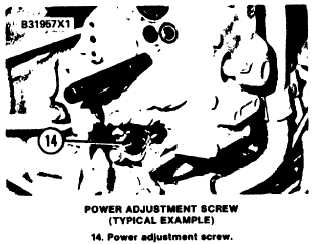

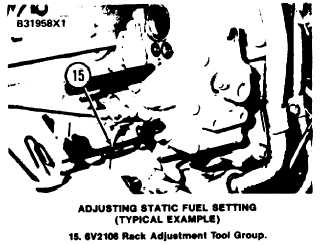

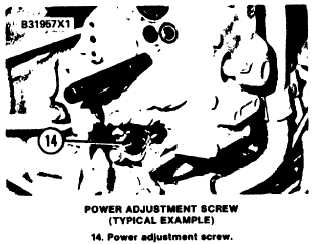

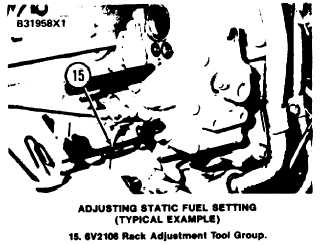

14. Install 6V2106 Rack Adjustment Tool Group

(15) on power adjustment screw (14) and lock-

nut.

15. Loosen the locknut and turn the power adjust-

ment screw to change the static fuel setting.

Turn the power adjustment screw clockwise to

decrease the static fuel setting. Tighten the

locknut.

NOTE: One half of a turn of the power adjustment

screw will change the static fuel setting approxi-

mately 0.40 mm.

16.

Again check the static fuel setting. If the static

fuel setting is correct, remove all tools and in-

stall plug (9), covers (3 and 13). Install new

wire and seal.

MEASURING ENGINE SPEED

Tools Needed:

(8V3121 Multitach Group

The 6V3121 Multitach Group can measure engine

speed by the use of either the photo pickup and

reflective tape. or a magnetic pickup or tachometer

generator.

1-53