AIR INLET AND EXHAUST SYSTEM

TM 5-3805-263-14&P-2

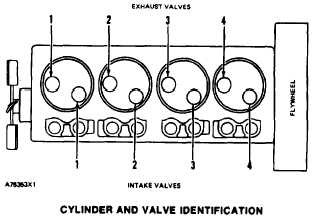

VALVE CLEARANCE

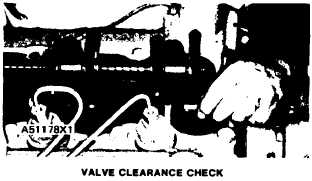

NOTE: Valve clearance is measured between the

rocker arm and the valves.

TESTING AND ADJUSTING

VALVE CLEARANCE CHECK: ENGINE STOPPED

Exhaust............

022 to 028 in. (0.56 to 0.71 mm)

Intake..............

.012 to .018 in. (0.30 to 0.46 mm)

NOTE: When the valve lash (clearance) is checked,

adjustment is NOT NECESSARY if the measure-

ment is in the range given in the chart for VALVE

CLEARANCE CHECK: ENGINE STOPPED. If

the measurement is outside this range, adjustment is

necessary. See the chart for VALVE CLEARANCE

SETTING: ENGINESTOPPED, and make the set-

ting to the nominal (desired) specifications in this

chart.

VALVE CLEARANCE SETTING: ENGINE STOPPED

I n t a k e . . . . . . . . . . . . . . . . . . . . . . . . .015 in. (0.38 mm)

E x h a u s t . . . . . . . . . . . . . . . . . . . . . . . .

.025 in. (0.64 mm)

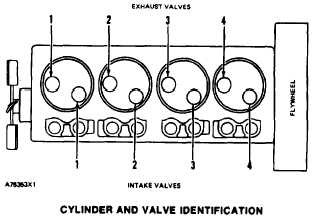

1. Put No. 1 piston at top center (TC) on the

compression stroke. Make reference to FIND-

ING TOP CENTER COMPRESSION POSI-

TION FOR NO. 1 PISTON.

2. Make an adjustment to the valve clearance on

the intake valves for cylinders 1 and 2. Make

an adjustment to the valve clearance on the

exhaust valves for cylinders 1 and 3.

3. Turn the flywheel 360° in the direction of en-

gine rotation. This will put No. 4 piston at top

center (TC) on the compression stroke.

4. Make an adjustment to the valve clearance on

the intake valve for cylinder 3 and 4. Make an

adjustment to the valve clearance on the ex-

haust valves for cylinders 2 and 4.

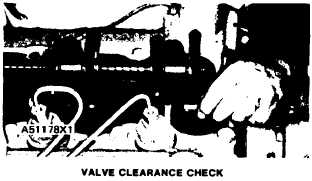

5. After valve adjustment is correct, tighten the

nuts for the valve adjustment screws to 22 ± 3

lb. ft. (28 ± 4 N•m).

1-60