FUEL SYSTEM

TESTING AND ADJUSTING

TM 5-3805-263-14&P-2

14. Hold a torque of 60 to 70 N•m (45 to 50 lb. ft.)

on adapter (11) in a clockwise direction, and

tighten bolt (6) that holds the timing gear to

270 ± 30 N•m (200 ± 20 lb. ft.).

15. Remove the timing bolt from the flywheel and

timing pin (4) from the fuel pump camshaft.

16. Rotate the crankshaft counterclockwise two

revolutions. If the timing bolt can be installed

in the flywheel and the timing pin can be in-

stalled in the fuel pump camshaft, the timing

is correct.

17. If either the timing pin or the timing bolt can

not be installed. do Steps 8 through 16 again.

Checking Engine Timing With 6V3100 Diesel

Engine Timing Indicator Group

CAUTION

The engine must be stopped while the timing

indicator is being connected.

1. Make reference to Operation Instructions inside

the lid of the 6V3100 Diesel Engine Timing

Indicator Group for complete instructions and

calibration.

2.

3.

4.

5.

6.

7.

8.

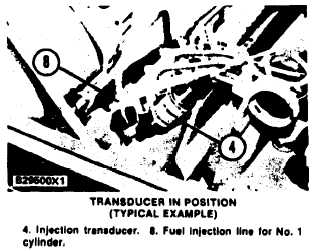

Loosen all fuel line clamps that hold No. I fuel

injection line and disconnect fuel injection line

(8) for No. 1 cylinder at the fuel injection pump.

Slide the nut up and out of the way. Put 5P7436

Adapter (7) in its place and turn adapter (7)

onto the fuel pump bonnet until the top of the

bonnet threads are approximately even with the

bottom of the “window” in the adapter.

Put the 5P7435 Tee Adapter (6) on the Injection

transducer (4) and put the end of the 5P7435

Tee Adapter (6) in the “window” of the 5P7436

Adapter (7).

Put fuel injection line (8) on top of 5P7435 Tee

Adapter (6). Install 5P7437 Adapter (5) and

tighten to 40 N•m (30 lb. ft.).

Remove plug (9) from the flywheel housing.

Install pipe adapter (3) into hole plug (9) was

removed from. Tighten only a small amount.

Push the TDC magnetic transducer (2) into the

pipe adapter (3) until it makes contact with the

flywheel. Pull it back out 1.6 mm (.06 in.) and

lightly tighten the knurled locknut.

Connect the cables from the transducers to the

Engine Timing Indicator. Make a calibration

check of the indicator.

Start the engine. Get the engine to operating

temperature. With the engine at low idle, check

engine timing. Increase engine speed and check

timing at 2300 rpm.

1-50