FUEL SYSTEM

LOCATING TOP CENTER COMPRESSION

POSITION FOR NO. 1 PISTON

No. I piston at top center (TC) on the compression

stroke is the starting point for all timing procedures.

NOTE: The engine is seen from the flywheel end

when direction of crankshaft rotation is given.

1. Remove the valve cover.

2.

3.

Use a 1 1/8 inch socket on the front crankshaft

pulley bolt and rotate the crankshaft clockwise

approximately 30 degrees. The reason for this

step is to be sure the free play is removed from

the timing gears when the engine is put on top

center.

Remove the plug from the timing hole in the

flywheel housing. Rotate the crankshaft until a

3/8"- 16 NC bolt, 50.8 mm (2.00 in.) long, can

be turned into the flywheel through the timing

hole in the flywheel housing. No. I piston is now

on top center.

NOTE: If the crankshaft is turned beyond top center

do Steps 2 and 3 again.

4. The intake and exhaust valves for No. 1 cylinder

will be closed if No. 1 piston is on the compres-

sion stroke. You can move the rocker arms up

and down with your hand.

5. If No. 1 piston is not on the compression stroke,

remove the timing bolt and rotate the crankshaft

counterclockwise 360°. Install the timing bolt.

The No. 1 piston is now at top center on the

compression stroke.

TESTING AND ADJUSTING

TM 5-3805-263-14&P-2

CHECKING TIMING BY

FUEL FLOW METHOD

Tools Needed:

1P540 Flow Checking Tool Group

5P6524 Engine Timing indicator Group

9S215 Dial Indicator

958883 Contact Point, 12.7 mm (.50 in.) long

5P7266 Adapter

3P1565 Collet

6V2056 Rod, 130.00 mm (5.118 in.) long

6V2057 Contact Point

6V2023 Flow Checking Adapter

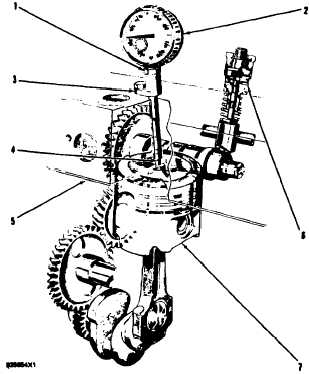

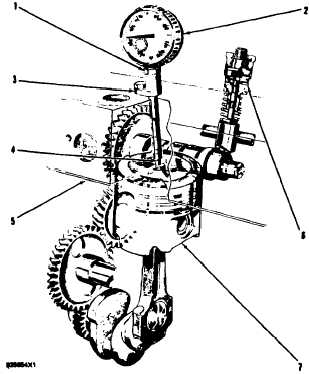

MEASUREMENT OF PISTON TRAVEL

1. 3P1565 Collet. 2. 9S215 Dial Indicator and 9S8883

Contact Point.

3. 5P7266 Adapter. 4. 6V2056 Rod,

130.00 mm (5.118 in.) long. 5. Cylinder heed. 6. Inlet

port. 7. Piston.

The fuel flow timing method is the most ac-

curate method to check the timing of the engine.

The distance of piston (7) from top center when

inlet port (6) just closes can be determined by the

use of the procedure that follows. Use the chart

to find the conversion of dial indicator reading to

crankshaft degrees.

NOTE: The fuel flow method CAN NOT be used

with 3300 Series Direct Injection engines that have

21 or more degrees BTC timing.

NOTE: The fuel system timing has a tolerance of

± 1°.

1-45