POWER TRAIN

DISASSEMBLY AND ASSEMBLY

TRANSMISSION GEARS

TM 5-3805-263-14&P-2

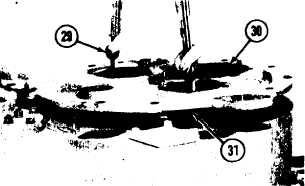

31. Install two 3/8”-16 NC forged eyebolts (29)

in cover (30). Fasten a hoist to the eyebolts.

32. Lift the cover. Install O-ring seal (3 1) on the

cover. Put the cover in position on the case.

NOTE: The dowel in the idler gear shaft must be in

alignment with the groove (slot) in the bottom of

the cover.

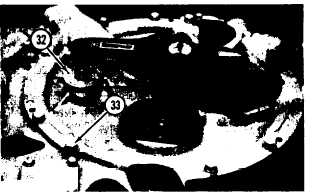

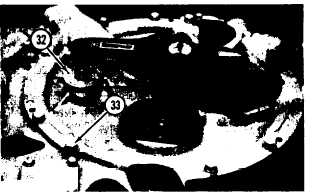

33. Install bolts (33) and the lockwashers that

hold the cover to the case.

34. Install the O-ring seal and retainer (32).

Install the bolt that holds the retainer and

tighten it to a torque of 85 ± 5 lb. ft. (11.8

± 0.7 mkg).

NOTE: Do Steps 35 through 38 for each cage.

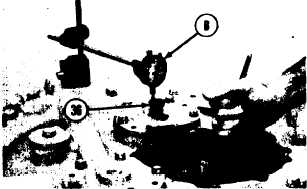

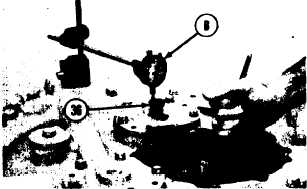

35.

36.

37.

38.

39.

Lower the temperature of bearing cup (35).

Install the bearing cup in cage (34). Install

the O-ring seal on the cage. Remove the

plug from the center of the cage.

Put the original amount of shims in position

on the cage. Install the cage in the cover.

Install the bolts and the lockwashers that

hold the cage to the cover and tighten them

evenly.

Install a 5/8”-11 NC x 6” long bolt (36) in

the directional clutch shaft and through the

hole in the cage. Make sure the head of the

bolt has a smooth surface. Install tooling

(B) as shown.

Check the end clearance of each directional

clutch by prying under the input gear with a

crowfoot bar. The end clearance must be

.002 to .006 in. (0.05 to 0.15 mm). Add or

remove shims to get correct end clearance.

Remove tooling (B) and the bolt. Install the

plugs in the cages.

2-115