POWER TRAIN

TM 5-3805-263-14&P-22

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

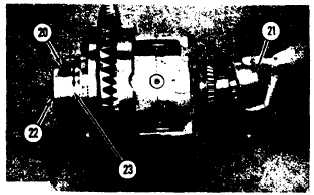

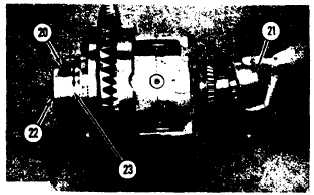

Install the bearing cup and nut (22) in cage

(20). Install ring (23) and the two seals on

the cage.

Put the cage in position over the bearing.

Install the nut and the bearing cup in cage

(21). Put cage (21) in position over the

bearing.

Fasten a hoist and a strap to the differen-

tial. Put the differential in position on the

carrier. Install the ring and seal between the

carrier and cage (20). Make sure the opening

in the cage is in alignment with the ring and

seal.

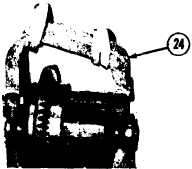

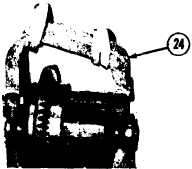

Put cap (24) in position over the studs in

the carrier. Install the dowel in cage (2 1).

Make sure the dowel is in alignment with

the hole in cap (24).

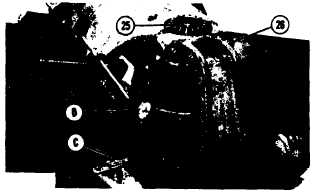

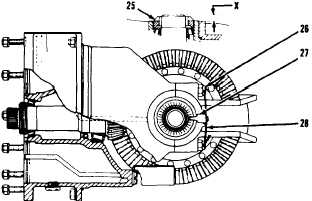

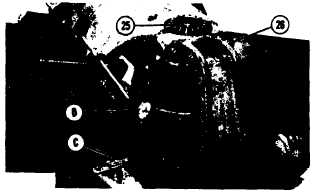

Install nuts (26) that hold the cap to the

carrier. Tighten the four nuts to a torque of

75 lb. ft. (10.4 mkg).

Put the differential in position as shown.

Put tooling (D) in position on the differen-

tial and against a tooth on the bevel gear.

Turn the bevel gear to measure the gear

clearance (backlash) between the pinion and

the bevel gear.

Make an adjustment to nut (22) under the

bevel gear with tool (C), while keeping nut

(26) finger tight against the top bearing, to

get a gear clearance (backlash) of .008 +

.004 - .003 in. (0.20 + 0.10 -0.08 mm).

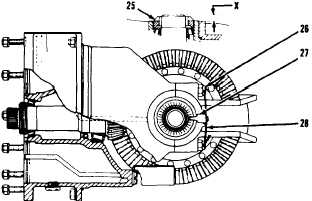

Loosen nut (25). Tighten the nut by hand

to remove the end play. Tighten nut (26) 1

to 1 1/2 notches and measure the amount

of change in dimension (X) with tooling

(D). Dimension (X) must change by .005 ±

.002 in. (0.18 ± 0.05 mm).

Tighten nuts (26) to 280 ± 20 lb. ft. (380

± 27 N•m). Turn the differential and

measure the gear clearance (backlash)

again.

Put locks (27) in position on the cap. Install

the locks and bolts that hold locks (27).

Bend the locks against the bolts. Install

wires (28) through the studs and nuts on

each side of the differential.

Install all the C-ring seals on the differen-

tial.

end by:

a) install differential

2-84.