POWER TRAIN

15.

16.

17.

18.

19.

20.

21.

22.

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL

TM 5-3805-263-14&P-2

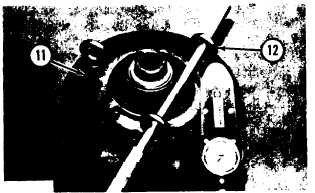

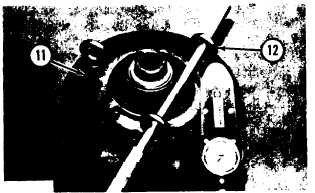

Install the seals on the outside and the

inside of the piston. Install the seals so the

lips are toward the bottom of the bore for

the piston in the piston housing. Put some

clean SAE 30 oil on the lips of the seals.

Install the piston in housing (10).

Heat bearing (9) in oil to a temperature of

275° F (135° C). Install bearing (9) on the

hub of piston housing (10).

Put piston housing (10) and the bevel gear

in position on clutch housing (7). Make sure

the holes in both housings and the bevel

gear are in alignment.

Install three 5/8°-11 NC forged eyebolts

(12) in piston housing (10). Install the bolts

and the washers that hold the piston hous-

ing to the bevel gear and the clutch housing.

Put a bar in position as shown in the

eyebolts. Tighten bolts (11) to a torque of

185 + 10 lb. ft. (25.6 + 1.4 mkg).

Remove the bar and the eyebolts.

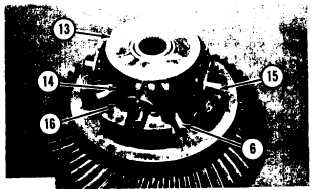

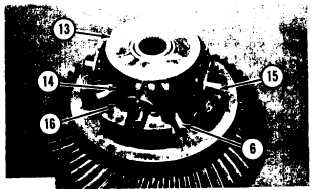

Turn the housings and the bevel gear over.

Be careful that gear (6) does not fall out.

Install the brass bearings in spider gears (14)

with tool (E) and an arbor press.

Install gears (14) and brass washers (16) on

spider (15). Put the spider and the gears in

position on the clutch housing as shown.

NOTE: Make sure the notches in the brass washers

are up.

23. Install gear (13) as shown on the spider

gears. Install the large brass washer on the

face of gear (13). Make sure the hole in the

washer is in alignment with the dowel in the

housing.

24.

25.

Put housing (18) in position on the clutch

housing. Tool (F) can be used to make sure

the notches in washers (16) are in alignment

with the dowels in housing (18). Install

bolts (19) the washers. Tighten the bolts to

a torque of 60 ± 5 lb. ft. (8.3 ± 0.7 mkg).

Heat bearing (17) in oil to a temperature of

275° F (135° C). Install bearing (17) on the

hub of housing (18).

2-83