POWER TRAIN

TM 5-3805-263-14&P-2

5.

6.

7.

8.

9.

10.

11.

12.

13.

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL

Heat bearing (4) in oil to a temperature of

275oF (135oC).

Install bearing (4) on pinion (1). Make sure

the bearing is in its seat in the bearing cup.

Lift the carrier and remove the block from

under the pinion. Put the carrier on the

floor. Remove tooling (A) from the carrier.

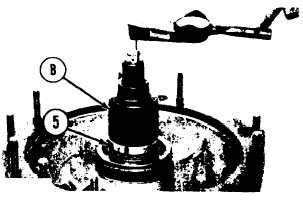

Install the washer, the lock and nut (5) on

the pinion. Do not tighten the nut.

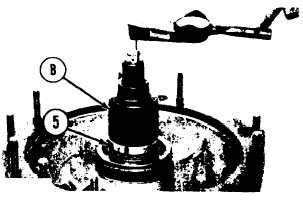

Put two .250 in. (6.35 mm) dowels in the

splines of the pinion. Put the dowels in

position 180o apart. Install tooling (B) over

the pinion and the dowels.

Check the amount of torque needed to

move the pinion without any preload on the

pinion bearings. Remove the torque wrench

from tooling (B).

Install a ratchet on tooling (B).

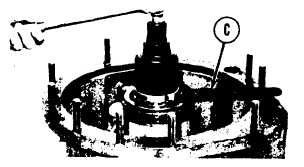

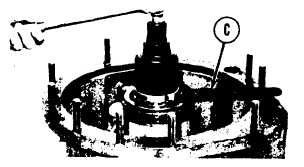

Install tool (C) on nut (5). Tighten nut (5)

with tool (C) while holding the pinion with

the ratchet. Tighten the nut enough to get a

torque of 6 ± 4 lb. in. (6.9 ± 4.6 cm.kg)

more than the torque needed to turn the

pinion when the bearings were not preload-

ed. Remove tooling (B) and (C).

Put clutch housing (7) in position on the

floor as shown. Put a block of wood 2 1/2

in. (63.5 mm) high in the center of the

housing. Put gear (6) in position on the

block.

Put the pressure disc in position in clutch

housing (7). Install the eight discs and the

seven disc assemblies in the housing starting

with a disc.

NOTE: Put clean SAE 30 oil on the discs and disc

assemblies (8) at installation.

14. Put the large brass washer on the face of

gear (6). Make sure the hole in the washer is

in alignment with the dowel in the housing.

2-82