POWER SHIFT TRANSMISSION

TESTING AND ADJUSTING

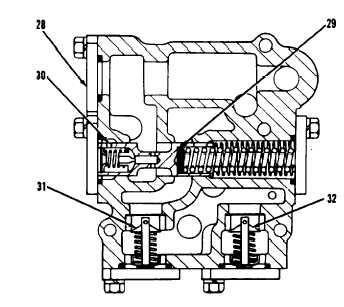

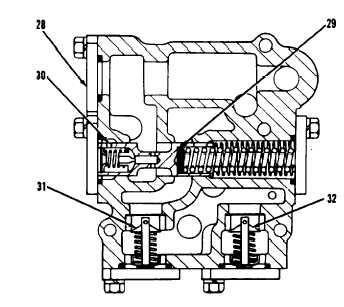

RELIEF VALVE GROUP

28. Relief valve group. 29. Spacars. 30. Main relief valve.

3 1 . R e l i e f v a l v e f o r o i l c o o l e r . 3 2 . R e l i e f v a l v e f o r

transmission lubrication oil.

PRESSURE CHANGE TO THE VALVES

BY REMOVAL OR ADDITION OF ONE SPACER

Spacer

Thickness

Change in

Where

Part No.

in.

mm

psi

kPa

Used

5 M 3 4 9 2

. 0 1 0

0 . 2 5

5 . 4

3 7 . 0

M a i n

7M1397

.036

0 . 9 1

1 9 . 6

1 3 4 . 5

R e l i e f

7M1396

.062

1 . 5 7

3 3 . 7

2 3 1 . 4

V a l v e ( 3 0 )

5 M 3 4 9 2

.010

0 . 2 5

2.01

13.87

Modulating

7M1397

. 0 3 6

0.91

7 . 2 5

5 0 . 0 0

Reducing

7M1396

. 0 6 2

1.57

12.50

8 6 . 0 0

Valve (21)

CLUTCHES ENGAGED

TRANSMISSION

IN TRANSMISSION

SPEED

FORWARD

R E V E R S E

FIRST

SECOND

T H I R D

F O U R T H

F I F T H

SIXTH

NEUTRAL

l, 5, and 6

1, 4, and 6

1, 3, and 6

1, 5, and 7

1, 4, and 7

1, 3, and 7

3 and 7

2, 5, and 6

2, 4, and 6

2, 3, and 6

2, 5, and 7

2, 4, and 7

2, 3, and 7

3 and 7

TM 5-3805-263-14&P-2

3P891 TRANSMISSION OIL PUMP

BENCH TEST SPECIFICATIONS

T y p e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear

Number of sections

. . . . . . . . . . . . . . . . . . . . . . . . . . .

T w o

Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clockwise

Output large section:

Using SAE 10W oil at 120°F

( 4 9o ) ] . . . . . . . . . . .

42.5 U.S. gpm (161 litre/min) minimum

A t a s p e e d o f . . . . . . . . . . . . . . . . . . . . . . . .

2200 rpm

A t a p r e s s u r e o f . . . . . . . . . . . . . . . . .

60 psi (415 kPa)

Output small section:

[Using SAE 10W oil at 120oF

(49o C)] . . . . . . . . 23.7 U.S. gpm (90 litre/min) minimum

At a speed of

. . . . . . . . . . . . . . . . . . . . . . . .

2200 rpm

At a pressure of . . . . . . . . . . . . . . . .

325 psi (2250 kPa)

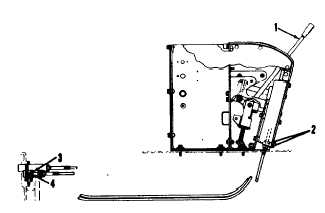

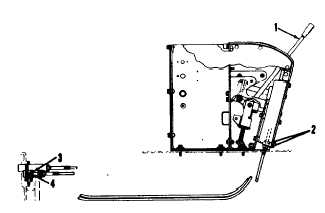

ADJUSTMENT OF CABLES FOR

TRANSMISSION CONTROL

WARNING: Do not make any adjustments

to the cables with the engine running.

Speed and Direction Cables

1. Be sure all of pins (4) for the ends of the

cables are in slots (3) of the valve spools.

2. Make an adjustment to nuts (2) on the ends of

the cable housing so the extension of the

threads on both sides is the same.

SPEED AND DIRECTION CABLE CONTROLS

1. Selector lever. 2. Nuts. 3. Slot. 4. Pin.

3. Put selector lever (1) in the REVERSE-NEU-

TRAL position. Remove the front cover for

the controls.

4. Remove the bolt and lockwasher that holds

the end (5) to the lever (6).

5. Pull up on the end of the cable as far as it will

go. Make an adjustment to end (5) until the

hole in the end is in alignment with the hole in

lever (6).

2-37