3304 VEHICULAR ENGINES

TM 5-3805-263-14&P-2

SPECIFICATIONS

CYLINDER LINER

(1)

(2)

(3)

Bore in liner

( n e w ) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.751 ± .001 in. (120.68 ± 0.03 mm)

Use again maximum bore when measured near upper end of the

wear surface of the cylinder liner . . . . . . . . . . 4.755 in. (120.78 mm)

Thickness of flange

on liner . . . . . . . . . . . . . . . .4048 ± .0008 in. (10.282 ± 0.020 mm)

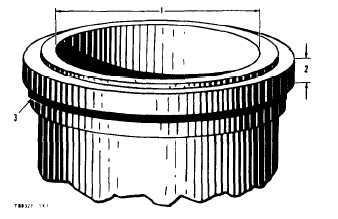

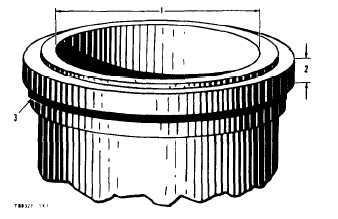

Filler band.

Cylinder Liner Installation

Put liquid soap on bottom liner bore in block. on grooves in lower

liner, and on O-rings. Install O-rings on liner. Put filler band (3) in

engine oil for a moment and install on liner. Immediately Install liner

in cylinder block (before expansion of filler band).

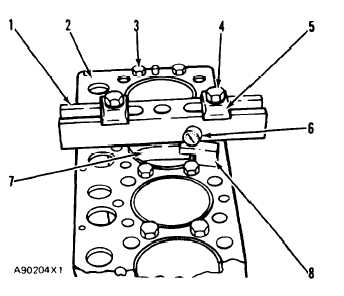

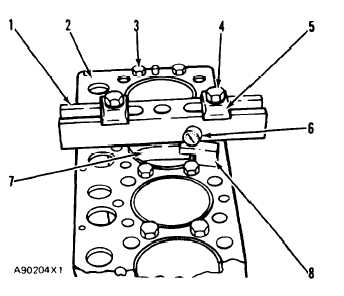

CYLINDER LINER PROJECTION

1. Install gasket and spacer plate (2) with bolts (3) and two 1S379

Washers. Tighten bolts (3) evenly in four steps

lst step

. . . . . . . . . . . . . . . . . . . . . . . .

10 lb. ft. (14 N•m)

2nd step

. . . . . . . . . . . . . . . . . . . . . . . . .

25 lb. ft. (35 N•m)

3rd step . . . . . . . . . . . . . . . . . . . . . . . . . . .

50 lb. ft. (70 N•m)

4th step . . . . . . . . . . . . . . . . . . . . . . . .

70 lb. ft. (95N•m)

2. Install tools as shown. Tighten bolts (4) evenly in four steps:

lst step

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5lb ft. (7 N•m)

2nd step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 lb ft. (20 N•m)

3rd step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25 lb. ft. (35 N•m)

4th step . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50 lb. ft. (70 N•M)

3. Measure cylinder liner projection with dial indicator (6) in lP2402

Gauge Body (8) as shown. Measure at four places around each

cylinder liner near the clamped area.

Cylinder liner projection measurement for any cylinder

liner must be . . . . . . . . . . . . . . . .0013 to .0069 in. (0.033 to 0.175 mm)

Maximum permissible difference between all

four measurements . . . . . . . . . . . . . . . . . .002 in. (0.05 mm)

Maximum permissible difference between average projection

of any two cylinder liners next to

each other . . . . . . . . . . . . . . . . . . .002 in. (0.05 mm)

Maximum permissible difference between average

projection of all cylinder liners under one

cylinder head . . . . . . . . . . . . . . . . . . . . .003 in. (0.08 mm)

NOTE: If liner projection is not correct, turn the liner to a new position

within the bore. If projection can not be corrected this way, move the

liner to a different bore

SHIM THICKNESS, COLOA CODE, AND PART NUMBER

.007 In.

.006 In.

.009 In.

.015 In.

.030 In.

(0.18 mm)

(0.20 mm)

(0.23 mm)

(0.38 m)

(0.76 mm)

BLACK

RED

GREEN

BROWN

BLUE

8S6045

8S6046

8S6047

6S6048

8S6049

4. Minimum permissible depth to machine counterbore to

adjust cylinder liner projection . . . . . . . . . . . . . 0 3 0 i n . ( 0 . 7 6 m m )

Maximum permissible depth to machine counterbore to

adjust cylinder liner projection . . . . . . . . . . . .

.045 in. (1.14 mm)

Install a .030 in. (0.76 mm) shim plus any added shims necessary

to get the correct cylinder liner projection.

NOTE: Be sure that the .030 in. (0.76 mm) shim is directly under the

cylinder liner flange.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Put liquid gasket on the top of the top shim and on the bottom

of the bottom shim before installing.

Crossbar (from 8B7548 Puller).

Spacer plate.

S1589 Bolt with two 1S379 Washers.

1D4595 Bolt.

3H465 Plate.

1P2403 Dial Indicator.

1P2394 Adapter Plate.

1P2402 Gauge Body.

1-240