ENGINE

DISASSEMBLY AND ASSEMBLY

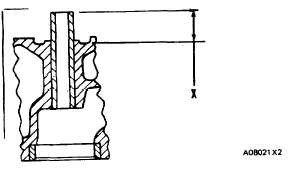

8.

9.

10.

CYLINDER HEAD

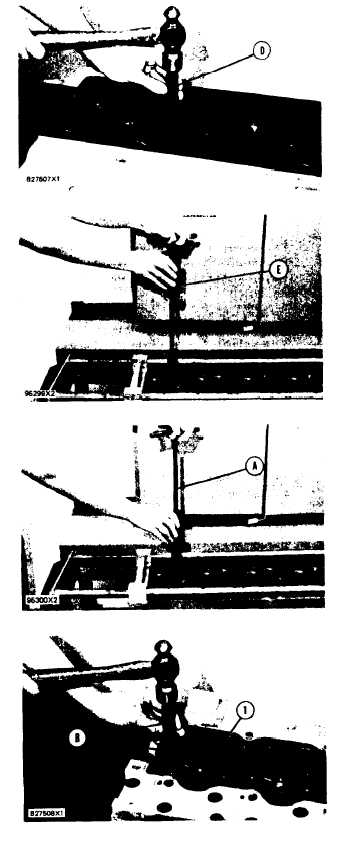

Use tooling (D) to remove the valve guides

from the cylinder head.

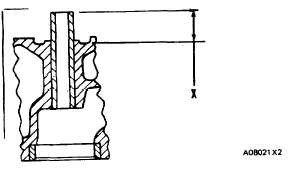

Use tooling (E) to remove the valve seat inserts

from the cylinder head.

Clean and remove any rough places (burrs)

from the valve seat bores.

ASSEMBLE CYLINDER HEAD

Tools Needed

A

B

C

D

E

9S3080

Valve Seat

Insert Group

1

7S8859

Guide Driver

1

7 S 8 8 5 8 B u s h i n g

5S1330 Valve Spring

Compressor

1

1

5S1322 Lock Inserter

1

8S2252 Carbon Seal Tool*

1

*The 8S2252 Carbon Seal Tool must have a modifi-

cation made to it before it can be used with the

8N7002 Fuel Injection Nozzle.

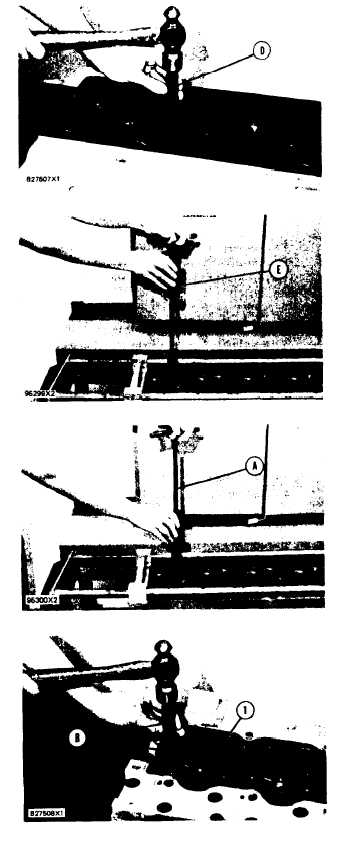

1. Lower the temperature of (freeze) the new

valve seat inserts. Use tooling (A) to install the

new valve seat inserts. Do not increase the dia-

meter of the extractor in the valve seat insert

when the insert is installed in the cylinder head.

2. Put clean oil on the outside diameter of the

valve guides. Use tooling (B) to install valve

guides (1) in the cylinder head. Tooling(B) will

install the valve guides so dimension “X” will

be correct. Dimension “X” must be 22.23 ±

0.25 mm (.875 ± .010 in.). The minimum in-

side diameter of the valve guides after installa-

tion must be 9.456 mm (.3723 in.). Clean the

valve guides after installation.

3. Grind the valve seat inserts according to speci-

fications given in SPECIFICATIONS section.

TM 5-3805-263-14&P-2

1-175