TM 5-3805-261-34

ENGINE MAINTENANCE.

13-3.

Cylinder Head Assembly Overhaul. (Sheet 4 of 6)

INSPECTION/REPAIR

4.

Using magnetic particle,

magnaflux or dye penetrant

method, inspect combustion

surface. Magnetic particle is

preferred. Discard and replace

head if cracks appear between

valve seats or between valve

seats and injector adapter holes.

If cracks are in other areas and

are less than 0.25 inch long and

0.125 inch deep, repair by

welding.

5.

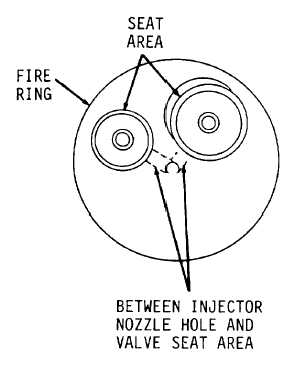

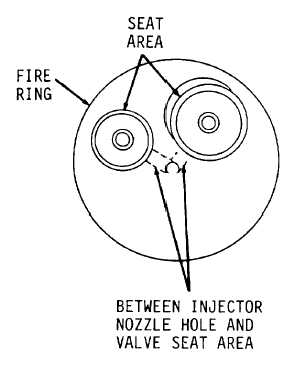

Inspect combustion surface for

damage and erosion across fire

ring, seat area, between injector

nozzle hole and valve seat area

(Figure 13-9). Discard and

replace head if erosion is

severe. If erosion is slight,

refer to step 11 for grinding

instructions.

6.

Using valve guide gage group,

plug gage or equivalent measure

inner diameter of both ends of

each of eight valve guides.

Maximum diameter is 0.3772 inch,

minimum diameter is 0.3723 inch.

Remove and replace guides worn

beyond limits. Refer to

paragraph 3-8.

7.

Inspect all threaded holes for

damaged threads, broken bolts or

studs. Extract all broken bolts

and studs. Repair damaged

threads with threaded inserts.

Figure 13-9.

Go to Sheet 5

13-13