TM 5-3805-261-34

HYDRAULIC SYSTEM MAINTENANCE.

10-19.

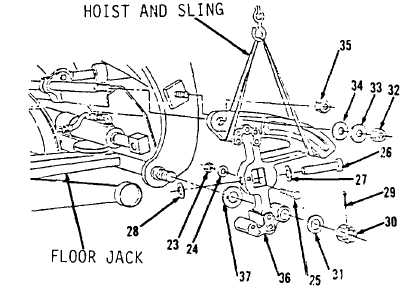

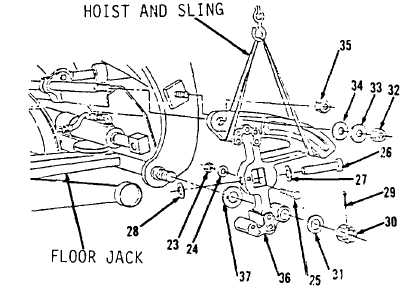

Hydraulic Side Shift Cylinder. (Sheet 5 of 7)

INSTALLATION

1.

Install bracket (41), four

washers (40) and bolts (39,

Figure 10-145).

2.

Using hoist and sling, position

cylinder (38, Figure 10-144).

Support with floor jack.

3.

Remove hoist and sling.

4.

Attach hoist and sling to bracket

(36, Figure 10-143).

5.

Using hoist and sling, position

washer (37) and bracket (36).

Use washer (37) as required to

get sliding fit with maximum 0.7

inch clearance between bracket

(36) and wear plate on circle

drive.

6.

Install bracket (36), nut (35),

washers (34 and 33), nut (32),

washer (31), nut (30) and new

cotter pin (29). Tighten nut

(30) to .00 clearance then back

off nut (30) one slot to install

cotter pin (29). Tighten nut

(35) to 1200 ft-lb. torque.

Maintain clearance given in

previous step 5.

7.

Install washers (28 and 27), pin

(26), bolt (25), washer (24) and

nut (23).

8.

Remove hoist and sling from

bracket (36).

Figure 10-143.

Go to Sheet 6

10-113