TM 5-3805-261-34

BRAKES TROUBLESHOOTING AND MAINTENANCE PROCEDURES.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

a.

AIR COMPRESSOR PASSES EXCESSIVE OIL, INDICATED BY OIL SEEPING FROM AIR STRAINER. (cont)

Step 4.

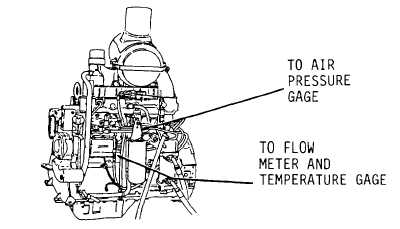

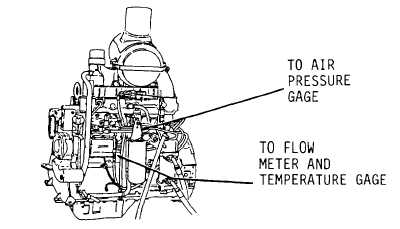

Check for poor compressor cooling (compressor runs hot). Check coolant flow and temperature through

compressor. Install suitable flow meter and temperature gage between compressor coolant outlet and

engine block (Figure 6-1). Start engine. Flow through compressor should be at least 2.5 gpm. Coolant

temperature should not exceed 200 degrees F. Stop engine.

If flow is not at least 2.5 gpm, check coolant lines and fittings for scales, kinks or restrictions. If coolant

temperature exceeds 200 degrees F., refer to Cooling System Troubleshooting.

Step 5. Check air system reservoir for build-up of dirt and water.

Drain reservoir. Refer to TM 5-3805-261-10.

Step 6. Check if air compressor runs loaded an excessive amount of time. Measure air system leakage. Install

suitable air pressure gage in air system (Figure 6-1). Start engine and let air pressure build up and

stabilize. Observe air pressure gage. System leakage should not exceed 1 psi pressure drop per minute

without brakes applied and 3 psi pressure drop with brakes applied. If leakage is excessive, look for

system leaks. Stop engine.

Repair system leaks, if necessary. Refer to paragraphs 6-9 and 6-11.

Figure 6-1.

6-3