TM 5-3805-261-34

BRAKES TROUBLESHOOTING AND MAINTENANCE PROCEDURES. (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

a.

AIR COMPRESSOR PASSES EXCESSIVE OIL, INDICATED BY OIL SEEPING FROM AIR STRAINTER.

(cont)

Step 7.

Check for loose end cover and cylinder block bolts.

Tighten bolts to standard torques. Repair or replace compressor after completing steps 1 thru 7, if

necessary. Refer to paragraph 6-13.

b.

NOISY COMPRESSOR OPERATIONS.

Step 1.

Check fit of drive gear on crankshaft. If crankshaft surface or its keyway are damaged, it is an indication

of loose drive gear components.

If drive gear is not installed correctly--remove and install. Refer to TM 5-3805-261-20.

Step 2.

Check for worn drive gear or pulley on air compressor crankshaft.

If drive gear or pulley is worn--replace. Refer to paragraph 6-13.

Step 3.

Check cylinder head.

If carbon build-up is detected in cylinder head, check for proper cooling of compressor. Refer to TM 5-

3805-261-20.

Step 4.

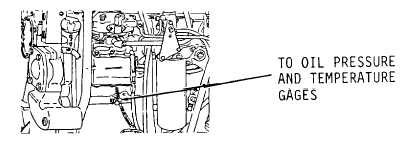

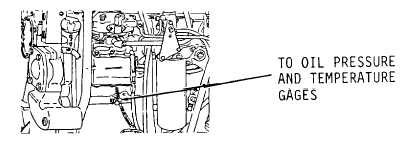

Check for worn bearings. Check oil pressure and temperature. Install suitable oil pressure and

temperature gages in oil supply line (Figure 6-2). Start engine. Oil pressure should be 5 psi at idle and 15

psi at maximum engine rpm.

Replace bearings if worn. Refer to paragraph 6-13. Repair or replace compressor after completing steps

1 thru 4, if necessary. Refer to paragraph 6-13.

Figure 6-2.

6-4