TM 5-3805-261-34

HYDRAULIC SYSTEM MAINTENANCE. (cont)

17-3.

Blade Tip Cylinder. (Sheet 4 of 6)

ASSEMBLY (cont)

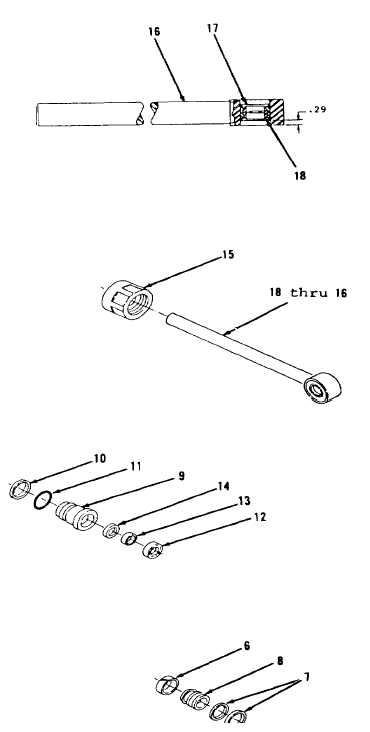

4.

Using bearing driver, install

ring (17) immediately next to new

bearing (18, Figure 17-15).

There should be a depth of 0.29

inch from outer surface of rod

assembly (16) to ring (17).

5.

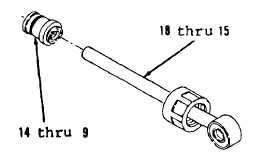

Remove items 18 thru 16 as an

assembly (Figure 17-13) from

vise.

6.

Position crown (15) on items 18

thru 16 as an assembly (Figure

17-13).

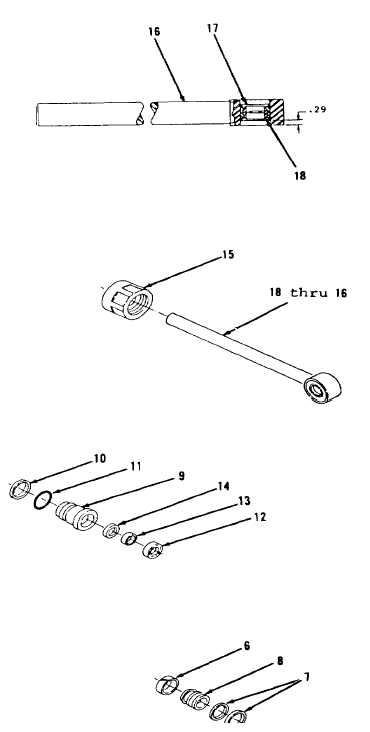

7.

Using clean oil, lubricate new

seals (14 thru 12), new preformed

packing (11) and ring (10, Figure

17-12).

8.

Using seal installer, install new

seals (14, 13 and 12), new

preformed packing (11) and ring

(10) in head (9). Lip of seal

(13) is toward inside of head

(9). Lip of seal (12) is toward

outside of head (9).

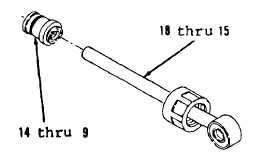

9.

Install items 14 thru 9 as an

assembly on items 18 thru 15 as

an assembly (Figure 17-11).

10.

Using seal expander, install new

seal assembly (7) and ring (6) on

piston (8, Figure 17-10).

Go to Sheet 5

17-10

Figure 17-

Figure 17-10.

Figure 17-

Figure 17-

Figure 17-15.