TM 5-3805-261-34

HYDRAULIC SYSTEM MAINTENANCE. (cont)

17-3.

Blade Tip Cylinder. (Sheet 2 of 6)

DISASSEMBLY

NOTE

For convenience, hydraulic

cylinder should be mounted on

a suitable repair stand. Oil

holes should be facing down

to prevent contamination.

1.

Using chain wrench, loosen crown

(15, Figure 17-7).

2.

Remove items 1 thru 3 as an

assembly.

3.

Using suitable bearing driver,

remove two rings (2) and bearing

(3) from cylinder (1, Figure

17-8). Discard bearing (3).

4.

Remove bolt (4) and washer (5,

Figure 17-9).

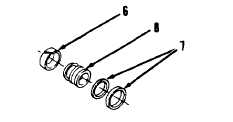

5.

Remove items 6 thru 8 as an

assembly.

6.

Remove ring (6) and seal assembly

(7) from piston (8, Figure

17-10). Discard seal assembly (7).

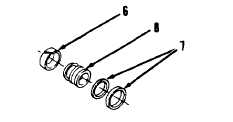

7.

Remove items 9 thru 14 as an

assembly (Figure 17-11).

Go to Sheet 3

17-8

Figure 17-10.

Figure 17-11.

Figure 17-9.

Figure 17-8.

Figure 17-7.