TM 5-3805-261-34

BRAKE MAINTENANCE.

14-20. Service Brakes. (Sheet 5 of 10)

DISASSEMBLY

NOTE

The proper tool must be used

in removing the cone (28).

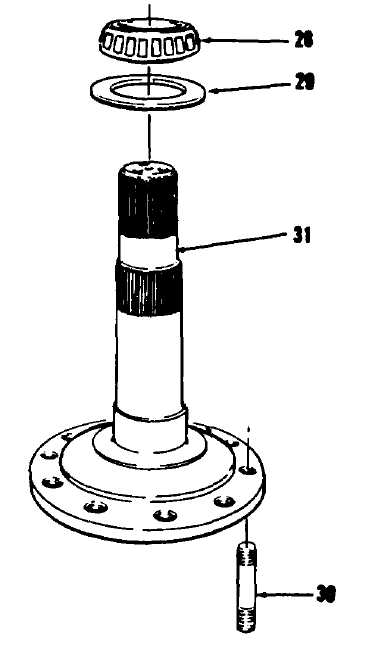

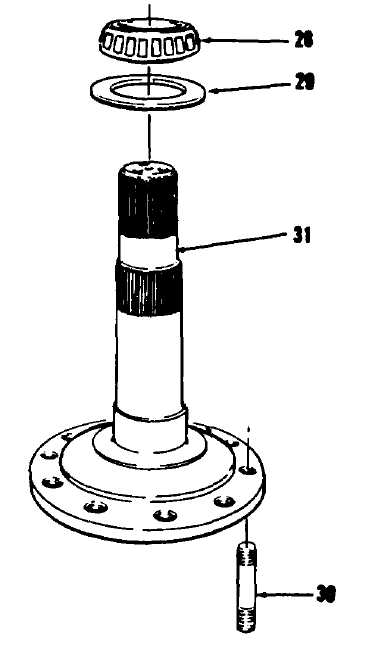

22. Using a bearing separator and

puller, remove cone (28) from

spindle (31, Figure 14-157).

23. Remove seal assembly (29) and ten

studs (30) from spindle (31).

Discard seal assembly (29).

CLEANING

Clean all parts. Refer to Chapter 2.

INSPECTION

Inspect all parts. Refer to Chapter

2.

ASSEMBLY

1.

Install ten studs (30) in spindle

(31, Figure 14-157).

2.

Using seal installer, install

seal assembly (29) in spindle

(31).

3.

Coat metal surface of seal

assembly (29) with engine oil SAE

30.

4.

Heat cone (28) in engine oil SAE

30 to a maximum temperature of

275 degrees F.

5.

Install cone (28) on spindle

(31).

Figure 14-157.

Go to Sheet 6

14-113