TM 5-3805-261-23-2

BLADE LIFT ARM REPLACEMENT - CONTINUED

0341 00

CLEANING AND INSPECTION

Clean and inspect all parts in accordance with WP 0020 00.

INSTALLATION

1.

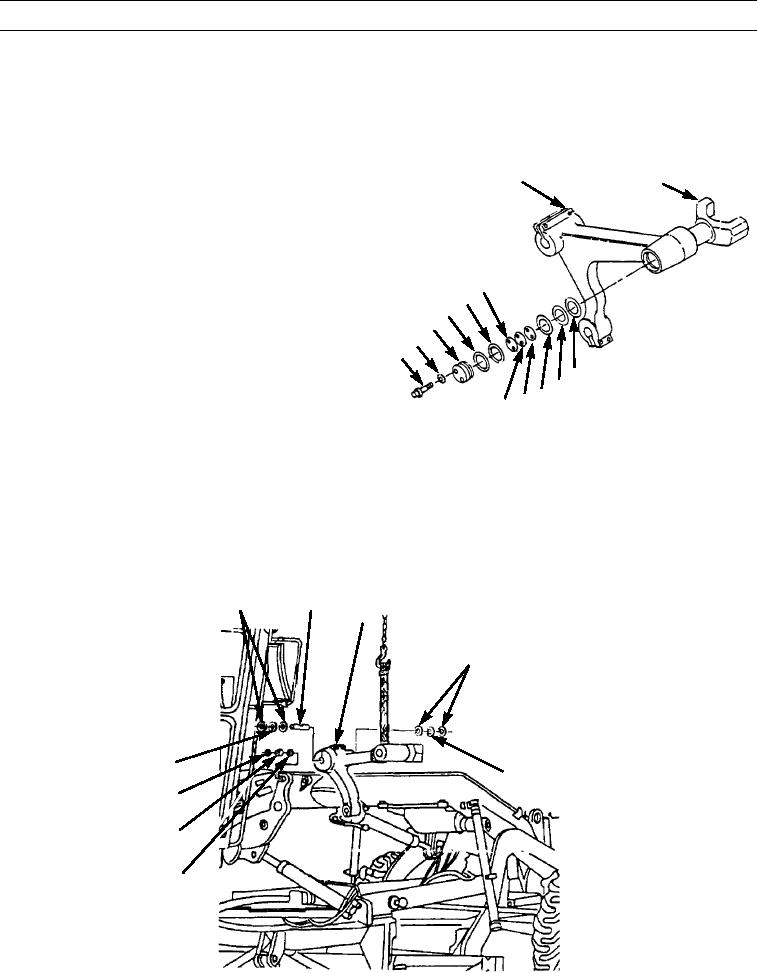

Install ring (31), new seals (32 and 33), and washers (28, 29, and 30) on yoke (20). Use expander assembly to install

seals.

NOTE

5

20

Install bearings so contact is made with

shoulders in arm.

2.

Use puller adapter, hydraulic pump, screw, puller

adapter, nut, and washer to install new bearings (26

19

18

and 27) in blade lift arm (5).

17

16

3.

Install yoke (20) in blade lift arm (5).

15

14

4.

Install washers (21, 22, and 23), shims (19, 24, and

21

25), new seals (17 and 18), retainer (16), two washers

23 22

(15), and bolts (14). Use shims (19, 24, and 25) to get

25 24

397-1682

0.01 in. (0.3 mm) maximum end clearance of yoke

(20). Yoke must rotate freely on blade lift arm (5).

5.

Use puller adapter, hydraulic pump, screw, puller adapter, nut, and washer to install two new bearings (13) in center of

machine frame. Install bearings to a depth of 0.359 to 0.391 in. (9.12 to 9.93 mm).

6.

Use bushing driver set to install four new seals (12). Lips of seals must be toward outside and even with outside surface.

7.

Attach sling to blade lift arm (10) and position on frame.

8.

Install blade lift arm (10), two washers (11), four washers (8), and pin (9).

8

9

10

8

11

11

12

13

12

397-1681

0341 00-5