TM 5-3805-261-23-2

LEANING WHEEL MECHANISM MAINTENANCE - CONTINUED

0303 00

INSTALLATION - CONTINUED

39.

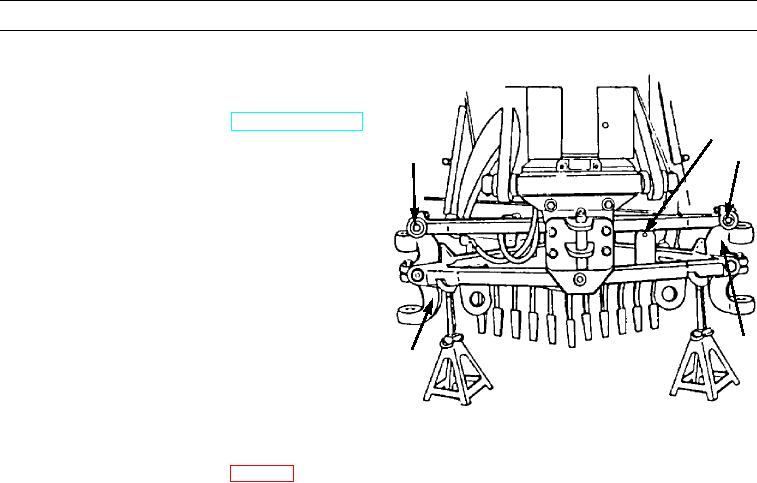

Remove ratchet assembly from arm assemblies (4 and

5) to put load on pins (1 and 3).

40.

Remove wheel lean lock pin (2) (TM 5-3805-261-10).

2

41.

Remove sling.

3

1

4

5

397-2295

42.

Lubricate fittings (WP 0023 00).

43.

Install steering arms and tie rod (WP 0301 00).

ADJUSTMENT

CAUTION

Always check camber after replacement of leaning wheel mechanism to prevent damage to machine. All

motor graders should have 2 degrees of positive camber on each front wheel. Neither wheel should be per-

pendicular to the ground which will cause excessive wear on tires.

1.

Raise front of machine.

2.

Use a plumb bob over the outside edge of one tire to obtain vertical reference.

0303 00-9