TM 5-3805-261-23-2

LEANING WHEEL MECHANISM MAINTENANCE - CONTINUED

0303 00

INSTALLATION

CAUTION

28

29

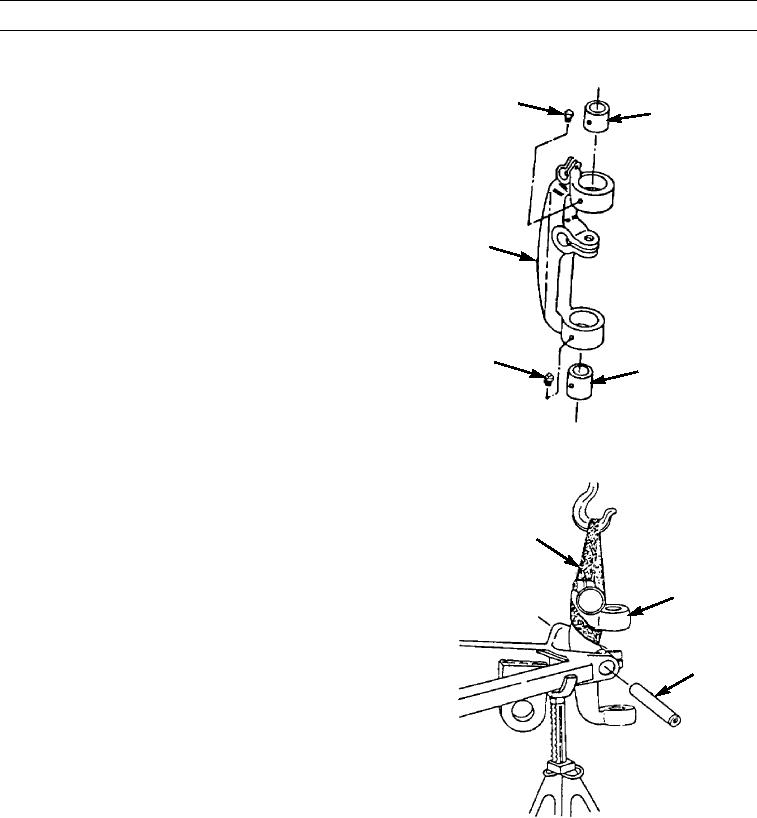

To prevent damage, special tools must

be used to install bearings.

These tools must also be used to

install bearing flush with upper sur-

face of collar on arm.

19.

Use assembled spacer, nut, pulling adapter, screw, nut,

bearing remover adapter, and hydraulic pump to install

4

bearing (29) flush with lower surface of collar on arm

(4).

20.

Install bearing (30).

21.

Install two fittings (28) on arm assembly (4).

28

30

397-4200

22.

Attach sling to arm assembly (4).

23.

Position arm assembly (4) on machine.

SLING

NOTE

Groove in pin must align with opening in arm assembly.

4

24.

Install pin (27).

25.

Remove sling.

27

397-4199

0303 00-6