TM 5-3805-261-23-1

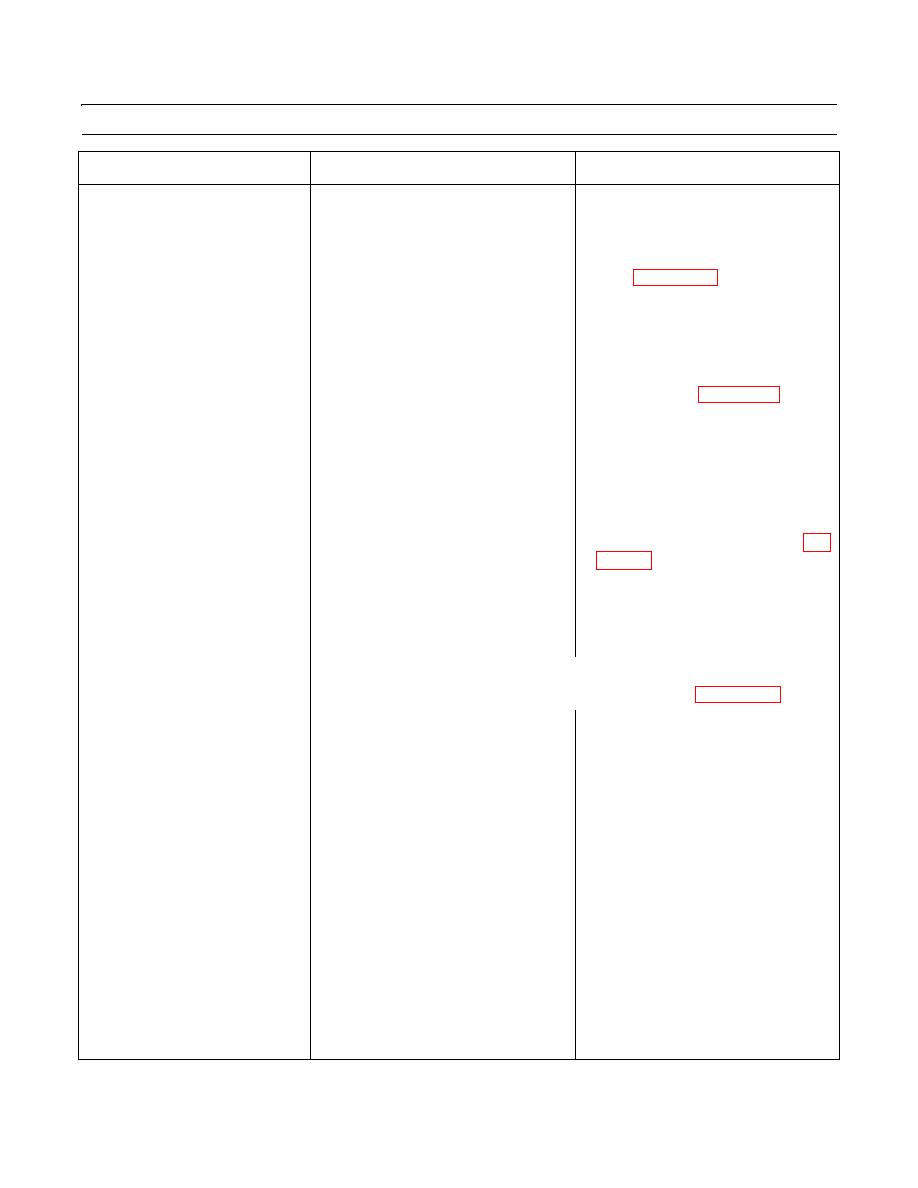

ELECTRICAL SYSTEM TROUBLESHOOTING PROCEDURES - CONTINUED

0008 00

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

Inspect batteries.

3.

Engine Will Not Crank.

1. Replace any cracked, leaking,

a. Visually inspect batteries for

cracks, leaks, and corroded or

corroded, or broken batteries or

broken terminal posts.

batteries with loose or broken terminal

posts (WP 0125 00).

2. Clean corroded terminal posts.

b. Check for loose, broken, or worn

1. Tighten any loose terminal or cable.

terminals and cables.

2. Replace any terminal or cable that is

broken or worn (WP 0125 00).

c. Check electrolyte level in each

Fill each cell to fill ring with distilled

battery cell (TM 9-6410-200-14).

water.

d. Perform specific gravity test (TM

1. Charge all batteries not meeting

9-6410-200-14). Batteries must test

requirements and recheck specific

1.240 or greater, temperature

gravity.

corrected, and each cell in battery

2. If 25 point variation still exists, battery

must test within 25 points of the

is defective and must be replaced (WP

others.

3. Tighten battery ground wire at tractor

chassis ground. Tighten battery

positive wire at starter solenoid. If the

problem still exists, go to Test 2.

NOTE

If STE/ICE-R is available, perform STE/ICE-R testing (WP 0014 00).

2.

Test batteries under load to determine

adequate current capability and

voltage drop during a 15 second

amperage load.