TM 5-3805-261-20

PRINCIPLES OF OPERATION.

1-24.

WHEELS AND TIRES. The six interchangeable rim and wheel assemblies are each mounted to the wheel spindle

flanges. Ten lug nuts are used to mount each wheel. Refer to paragraph 1-10 for location and paragraph 1-11 for tire

specifications.

1-25.

STEERING.

a.

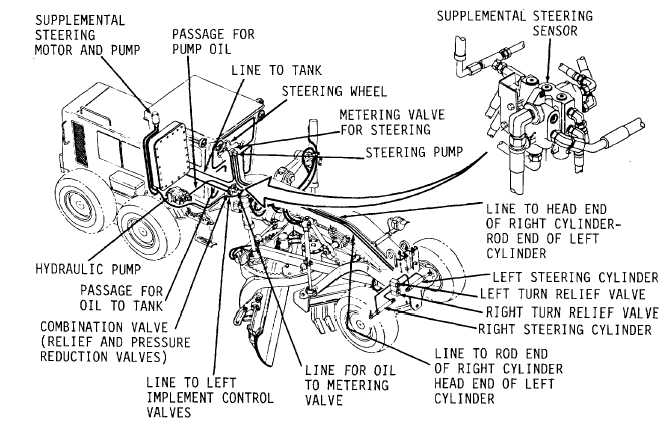

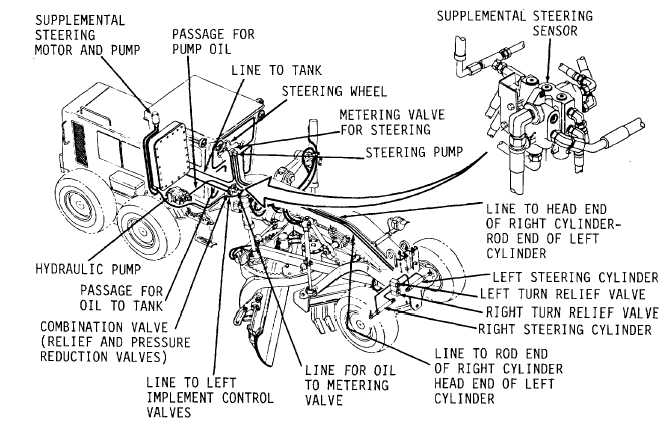

Steering (Figure 1-34). An engine driven, variable displacement pump mounted under the cab provides

hydraulic flow for the steering. Refer to paragraph 1-29. The steering wheel actuates a small hydraulic pump directing oil

to the two steering cylinders which steer the front wheels. An adjustable relief valve assembly is mounted at each side of

the chassis above the front axle. Refer to Appendix F for hydraulic system schematic. Also, refer to paragraph 1-21 for

location of hydraulic cylinders at front axle.

When the steering wheel is not being turned, the oil in lines and in cylinders, cannot move and the front wheels stay in

position. If the side of one of the front wheels hits a restriction (material that will not move), the positions of the front

wheels will move. The force on the side of the wheel causes an increase in the pressure of the oil in the cylinders and in

one of the lines to the cylinders. When the pressure of the oil in the line gets to 1700 psi, the relief valves opens. The high

pressure oil in the line goes through the open relief valve and into the other line to the cylinders. This lets the position of

the front wheels change.

Figure 1-34.

1-37