TM 5-3805-293-23-2

0031

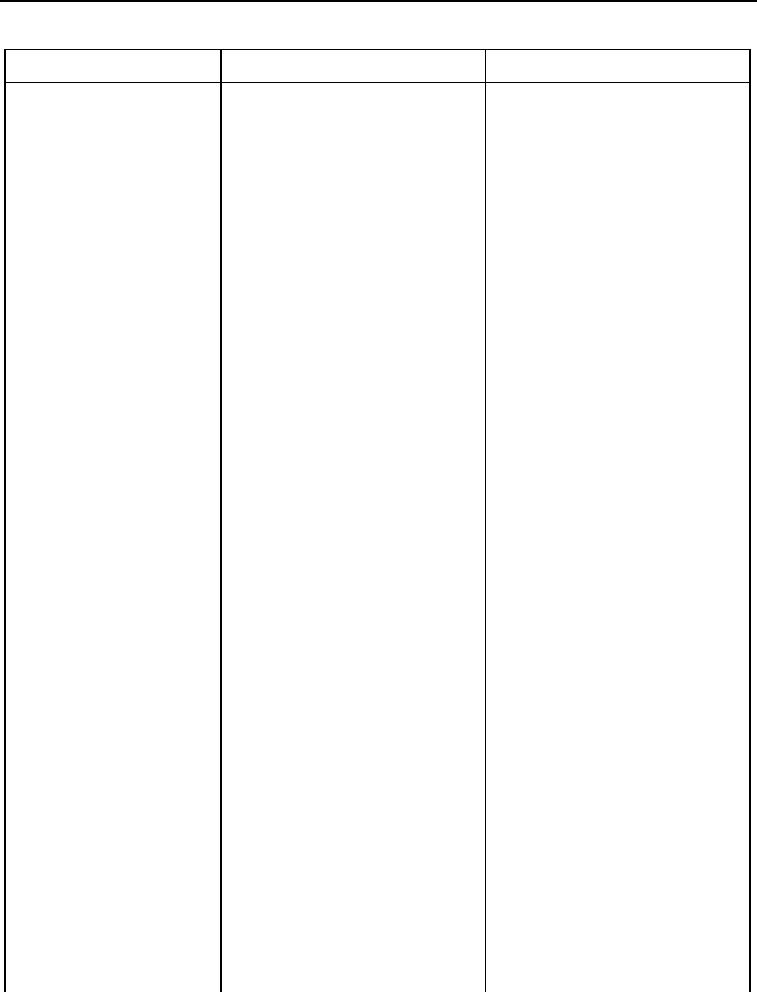

Table 1. Implement Code (2200-00 TO 2954-14) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

2211-05 Auxiliary Valve #1

6. Using MSD (WP 0006), select

2211-06 Code Becomes Active -

Port A Solenoid Current

Implement 120M and verify 2211-

Replace auxiliary valve #1 port A

Below Normal - Continued

06 is active.

solenoid (WP 0245).

Proceed to step 7.

2211-06 Code Not Active - Proceed

to Test Step 3.

7. Using MSD (WP 0006), select

2211-05 Code Active - Repeat

Implement 120M and verify 2211-

troubleshooting code from the

05 is active.

beginning.

2211-05 Code Not Active -

Troubleshooting complete.

Test Step 3. Test Cab Lower Har-

ness.

1. Disconnect front attachment har-

ness connector U-C1 (WP 0009,

Figure 121) from cab lower har-

ness connector P-C50 (WP 0009,

Figure 120).

2. Turn ignition switch and battery

disconnect switch to the OFF

position (TM 5-3805-293-10).

3. Using digital multimeter, test for

Resistance 5.0 Ohms or Less -

continuity between harness con-

Proceed to step 4.

nector U-C1 (WP 0009, Figure

Resistance More Than 5.0 Ohms -

121) terminal 6 and terminal 35.

Replace front attachment wiring

Resistance should be less than

harness (WP 0180).

5.0 Ohms.

Connect cab lower harness connector

P-C45 (WP 0009, Figure 72) to

implement 2 ECM J1 (WP 0009,

Figure 73).

Proceed to step 8.

4. Remove jumper wire between

harness connector U-C15 (WP

0009, Figure 246) terminal 1 and

terminal 2.

5. Install jumper wire between har-

ness connector P-C50 (WP 0009,

Figure 120) terminal 6 and termi-

nal 35.

6. Disconnect cab lower harness

connector P-C45 (WP 0009, Fig-

ure 72) from implement 2 ECM J1

(WP 0009, Figure 73) (WP 0268).

0031-109