TM 5-3805-293-23-2

0028

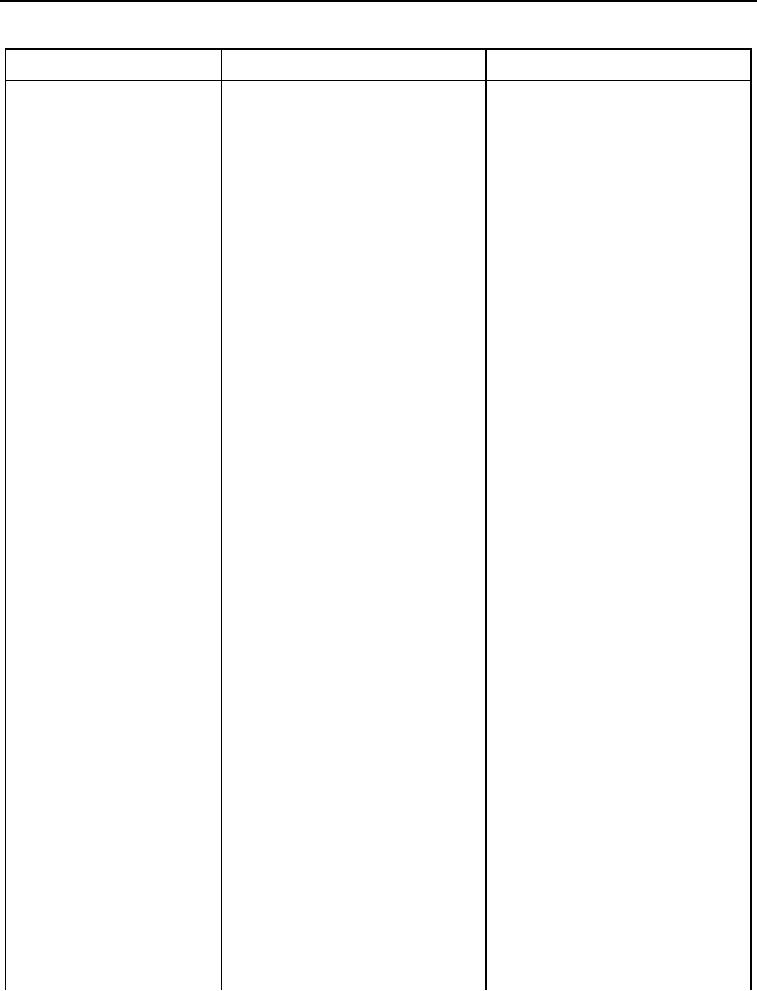

Table 1. Implement Code (2146-02 to 2156-08) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

2146-03 Articulation Lever

Test Step 1. Test for Active Code.

Position Sensor Voltage

1. Connect MSD (WP 0006). Select

0041-03 or 0041-04 Code Active -

Above Normal - Continued

Implement 120M ECM and check

Troubleshoot 0041-03 or 0041-04

if 0041-03 or 0041-04 is active.

code first before proceeding.

0041-03 or 0041-04 Code Not Active

- Proceed to step 2.

2. Using the MSD (WP 0006). Select 2146-03 Code Active - Proceed to

Implement 120M and verify 2146- Test Step 2.

03 is active.

2146-03 Code Not Active -

Troubleshooting complete.

Test Step 2. Test 8 Volt Power Sup-

ply Voltage to Sensor.

1. Turn ignition switch and battery

disconnect switch to the OFF

position.

2. Disconnect cab lower wiring har-

ness connector P-C51 (WP 0009,

Figure 118) from LH joystick con-

nector J1 (WP 0282).

3. Turn ignition switch and battery

disconnect switch to the ON posi-

tion.

4. Using digital multimeter, test for

Voltage Between 7.6 to 8.4 Volts -

voltage between harness connec-

Proceed to Test Step 6.

tor P-C51 (WP 0009, Figure 118)

Voltage Out of Specifications of 7.6

terminal 1 and terminal 3 ground.

to 8.4 Volts - Proceed to Test Step 3.

Voltage should be between 7.6 to

8.4 volts.

Test Step 3. Test for Open Rear

Chassis Wiring Harness.

1. Turn ignition switch and battery

disconnect switch to the OFF

position.

2. Disconnect the rear chassis wir-

ing harness connector FA-C20

(WP 0009, Figure 113) from trans-

mission ECM J1 (WP 0009, Fig-

ure 112).

3. Connect jumper wire between cab

lower wiring harness connector P-

C51 (WP 0009, Figure 118) termi-

nal 3 and machine ground.

0028-5