TM 5-3805-293-23-2

0021

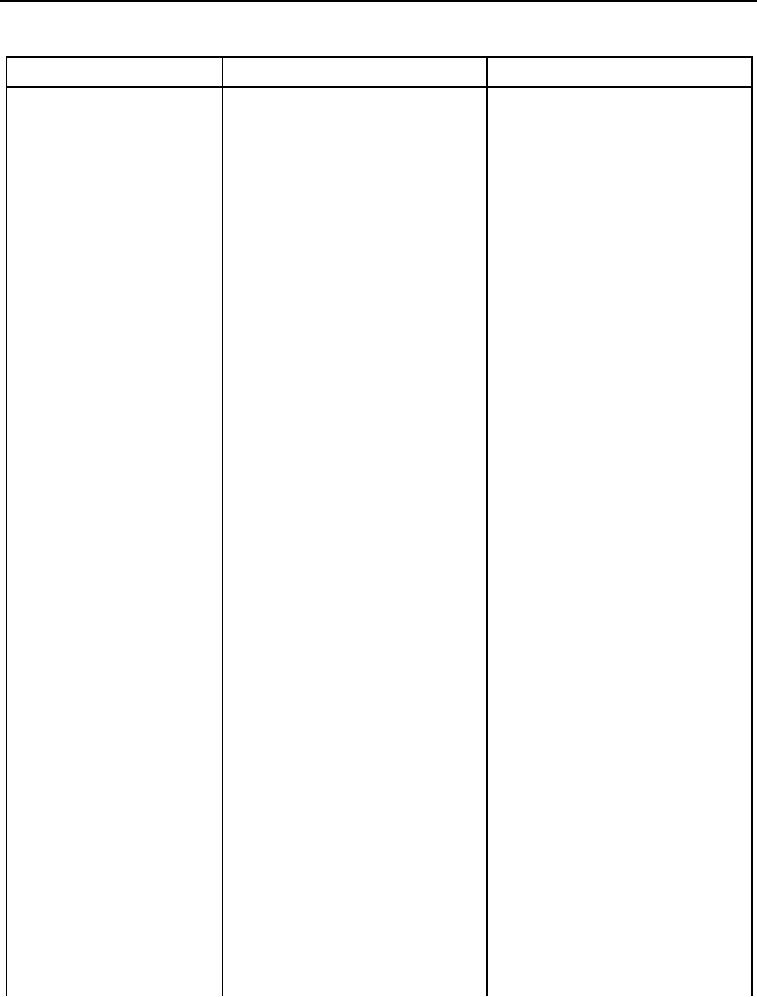

Table 1. Chassis Troubleshooting.

0021

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Temperature of Hydrau-

1. Connect MSD (WP 0006) and

Diagnostic or Event Codes Are

lic Oil is Too Hot

select Implement 120M ECM, and

Active - Repair diagnostic code

check for any active diagnostic or

(WP 0010).

event codes.

Diagnostic or Event Codes Are

NOT Active - Proceed to step 2.

2. Inspect hydraulic oil for correct

Oil Level Low - Fill hydraulic tank (LO

level and type (LO 5-3805-293-

5-3805-293-13) and perform oil con-

13).

figuration (WP 0217).

Oil Incorrect for Operating Condi-

tions - Drain and refill hydraulic tank

(WP 0217) and replace hydraulic filter

(WP 0208). Perform oil configuration

(WP 0217).

Machine Operating During High

3. Verify machine is not operating at

Ambient Temperatures - Allow

high system loads during high

machine to cool before resuming

ambient temperature

operation.

(TM 5-3805-293-10).

Machine Operating During High

System Loads - Reduce system load

during operation.

4. Start and run machine (TM 5-

3805-293-10).

5. Check hydraulic oil for bubbles in Bubbles Identified - Replace dam-

level indicator (bubbles can be

aged/leaking lines (WP 0133).

caused by leaking components)

No Bubbles - Proceed to step 6.

while machine is running. Inspect

for visible Class III leaks at all

hydraulic connections and tighten.

6. Check for kinked and damaged

Kinks or Damage Found - Replace

hydraulic lines.

kinked or damaged hydraulic lines

(WP 0133).

7. Perform Margin Pressure Adjust-

Pressure Cannot Be Adjusted or

ment (WP 0044).

Remains Low - Replace implement

steering pump control valve (WP

0121).

Pressure OK or Was Adjusted - Pro-

ceed to step 8.

8. Check pump signal relief control

Pressure Readings Do Not Change

- Replace signal resolver (WP 0246).

valve for proper setting, perform

Proceed to step 9.

Signal Resolver Test (WP 0044).

Pressure Readings Change - Trou-

bleshooting complete, proceed to

step 9.

9. Start and run machine (TM 5-

3805-293-10) to verify malfunc-

tion has been corrected.