TM 5-3805-293-23-2

0021

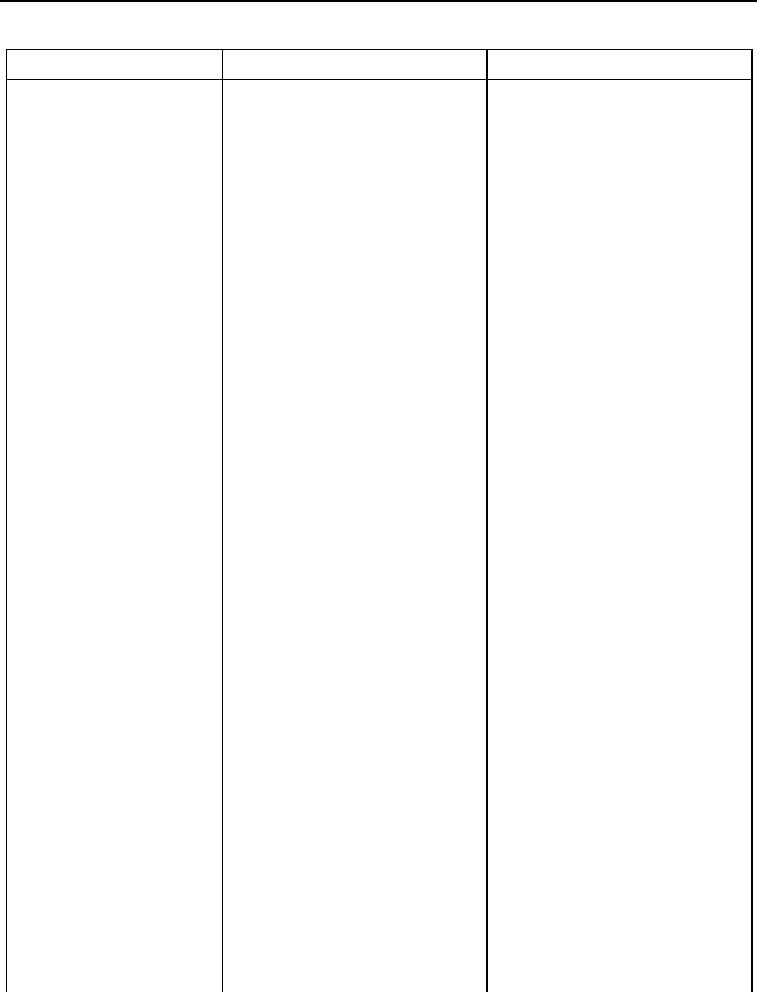

Table 1. Chassis Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. Hydraulic and Steering

1. Inspect hydraulic oil for correct

Oil Level OK - Proceed to step 2.

Pump Has No Pressure

level and type (LO 5-3805-293-

Oil Level Low - Drain and refill

13).

hydraulic tank (LO 5-3805-293-13)

and perform oil configuration (WP

0217).

Oil Incorrect for Operating Condi-

tions - Drain and refill hydraulic tank

(WP 0217) and replace hydraulic filter

(WP 0208). Perform oil configuration

(WP 0217).

2. Perform Margin Pressure Adjust-

Pressure Cannot Be Adjusted or

Remains Low - Replace implement

ment (WP 0044).

steering pump control valve (WP

0121).

Pressure OK - Proceed to step 3.

3. Start and run machine (TM 5-

3805-293-10) to verify malfunc-

tion has been corrected.

6. Response of One Imple-

1. Perform Margin Pressure Adjust-

Pressure Cannot Be Adjusted or

ment is Too Slow

ment (WP 0044).

Remains Low - Replace implement

steering pump control valve (WP

0121).

Pressure OK - proceed to step 2.

Signal Relief Valve Does Not

2. Check signal relief valve for

Respond Correctly - Perform adjust-

proper cycling, perform Adjust-

ment in test as directed.

ment for Signal Network (WP

0044).

Signal Relief Valve Responds Cor-

rectly - Troubleshooting complete,

proceed to step 3.

3. Start and run machine (TM 5-

3805-293-10) to verify malfunc-

tion has been corrected.

7. Response of All Imple-

1. Start and run machine (TM 5-

ments Are Too Slow

3805-293-10).

2. Check hydraulic oil for bubbles in Bubbles identified - Replace dam-

level indicator (bubbles can be

aged/leaking lines (WP 0121).

caused by leaking components)

No Bubbles - Proceed to step 3.

while machine is running. Inspect

for visible Class III leaks at all

hydraulic connections and tighten.

0021-6