TM 5-3805-293-23-2

0021

Table 1. Chassis Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Cylinder Rods Do Not

1. Check for contamination in

Hydraulic Oil Is Contaminated - Ser-

Move Evenly

hydraulic oil.

vice hydraulic oil (WP 0217) and

replace hydraulic oil filter (WP 0208).

Perform oil configuration (WP 0217).

2. Check implement and steering

Leaks Identified - Replace leaking

pump lines (WP 0133) for Class

implement and steering pump lines

III leaks.

(0133).

3. Check for Class III leaks at the

Leaks Identified - Replace leaking

hydraulic tank and hydraulic fan

hydraulic lines (WP 0133).

steering pump.

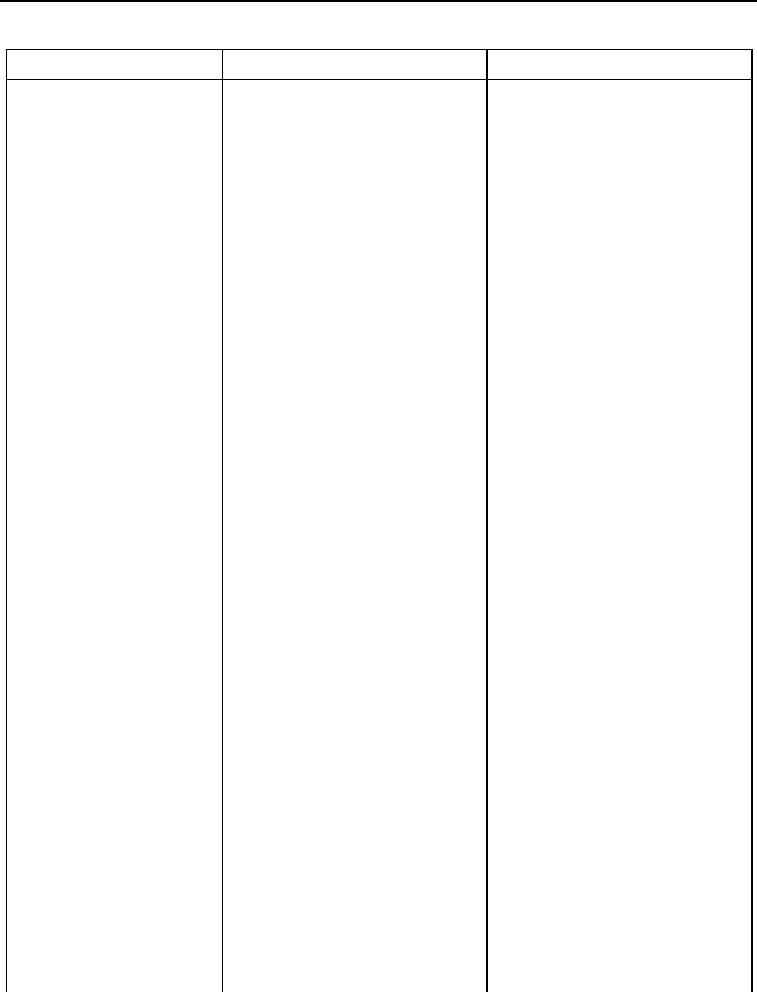

4. Check for Class III leaks at the fol- Leaks Identified - Repair affected

lowing cylinders (Figure 2): blade cylinder.

lift cylinders (WP 0309) seals,

a. Blade lift cylinders (WP 0309)

blade tip cylinder (WP 0311),

b. Blade tip cylinder (WP 0311)

seals, center shift cylinder (WP

c. Center shift cylinder (WP

0313), seals, side shift cylinder

0313)

(WP 0315), seals, and scarifier

d. Side shift cylinder (WP 0315)

cylinder (WP 0327) seals.

e. Scarifier cylinder (WP 0327)

No Leaks - proceed to step 5.

5. Check signal relief valve for

Signal Relief Valve Does Not

proper cycling, perform Adjust-

Respond Correctly - Perform adjust-

ment for Signal Network

ment in test as directed.

(WP 0044).

Signal Relief Valve Respond Cor-

rectly - Troubleshooting complete,

proceed to step 6.

6. Start and run machine (TM 5-

3805-293-10) to verify malfunc-

tion has been corrected.

0021-4