COOLING SYSTEM

TESTING AND ADJUSTING

TM 5-3805-263-14&P-2

C O O L I N G S Y S T E M

The engine has a pressure type cooling system. A

pressure type cooling system gives two advantages.

The first advantage is that the cooling system can

operate safely at a temperature that is higher than

the normal point where water changes to steam. The

second advantage is that this type system prevents

cavitation (air in inlet of pump) in the water pump.

With this type system it is more difficult for an air or

steam pocket to form in the cooling system.

The cause for an engine getting too hot is generally

because regular inspections of the cooling system

were not done. Make a visual inspection of the cool-

ing system before testing with testing equipment.

VISUAL INSPECTION OF THE COOLING

SYSTEM

1.

2.

3.

4.

5.

6.

7.

8.

Check coolant level in the cooling system.

Look for leaks in the system.

Look for bent radiator fins. Be sure that air flow

through the radiator does not have a restriction.

Inspect the drive for the fan.

Check for damage to the fan blades.

Look for air or combustion gas in the cooling

system.

Inspect the pressure cap and the sealing surface

for the cap. The sealing surface must be clean.

Look for large amounts of dirt in the radiator

core and on the engine.

TESTING THE COOLING SYSTEM

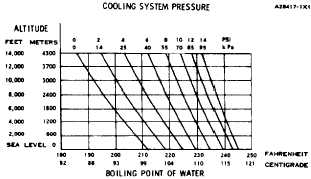

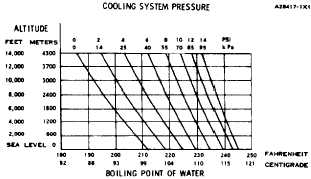

Remember that temperature and pressure work

together. When making a diagnosis of a cooling

system problem, temperature and pressure must

both be checked. Cooling system pressure will have

point (steam) of water.

an effect on cooling system temperatures. For an

example, look at the chart to see the effect of pres-

sure and the height above sea level on the boiling

Checking Coolant Temperatures

Tools Needed: 9S9102 Thermistor Thermometer Group.

The 9S9102 Thermistor Thermometer Group is

used in the diagnosis of overheating (engine running

too hot) or overcooling (engine running too cool)

problems. This group can be used to check the differ-

ent parts of the cooling system.

1-64