POWER TRAIN

TM 5-3805-263-14&P-2

ADJUSTMENT PROCEDURE FOR BACKLASH

OF RING GEAR AND PRELOAD OF

DIFFERENTIAL SUPPORT BEARINGS

THROUGH THE SIDE BORES IN THE

DIFFERENTIAL CASE

1. Disconnect the parking brake actuator by releasing it with

air pressure and removing the cotter pin and pin or use air

to keep the brake disengaged while adjustments are being

made.

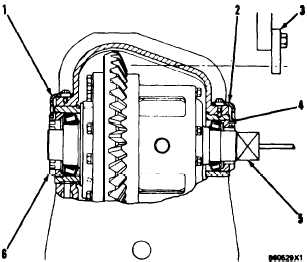

2. Remove locks (1) and (2) on bearing nuts (4) and (6). These

nuts are used to adjust the differential side bearing preloads.

3. Insert a drive axle shaft through both side gears of the dif-

ferential from the ring gear side (on nondifferentials. inser-

tion in one spline is enough). Turn the shaft with a pipe

wrench to rotate the differential as the bearings are being

adjusted.

4. Tighten nut (6) (on the side opposite the ring gear) as tight

as possible by hand while rotating the ring gear with the

axle shaft. The ring gear must be rotated for the bearings

to seat properly. While tightening nut (6) and rotating the

ring gear periodically, rock the ring gear against the bevel

gear so the backlash can be felt. An approximate backlash

of .010 in. (0.25 mm) should be established by loosening

or tightening nut (4) (ring gear side) while nut (6) is being

tightened.

5. When the approximate backlash of .010 in. (0.25 mm) has

been established, rotate the ring gear and tighten nut (4)

as tight as can be done with hands. Mark the position of

nuts (4) and (6) with a marking pen or something similar.

6. Tighten nut (4) an additional three notches.

7. An accurate backlash setting must now be made. Refer to

the Specifications section of the model being adjusted.

6. To measure the pinion to ring gear backlash, mount a dial

indicator with a magnetic base (5) to the end of the dif-

ferential housing assembly.

9. Fasten a block to one of the final drive mounting studs on

the main frame. Assemble dial indicator (5) so the indicator

plunger is against this block at a radius equal to the ring

gear diameter and will indicate the rotational movement of

the ring gear when it is rocked through its backlash with

the pinion gear.

10. Adjust nuts (4) and (6) equally to obtain the specified back-

lash. Check the marks made in Step 5 to assure a total

preload of three notches from band tight to the final locking

position has been maintained.

EXAMPLE: If nut (4) has to be loosened two notches, then nut (6)

should have been tightened two notches.

11. Install locks (1) and (2) that hold nuts (4) and (6) in position.

If the locks do not perfectly align in the notches, do not

advance the nuts more than a total of one half notch to align

the two locks.

2-134