POWER TRAIN

TM 5-3805-263-14&P-2

TRANSMISSION

ASSEMBLE TRANSMISSION

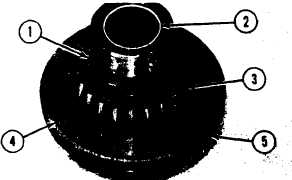

1. Install O-ring seal (5) on cage (4). Install

bearing (2) for the center shaft with tooling

(A).

2. Install bearing (3) and spacer (1) on cage

(4).

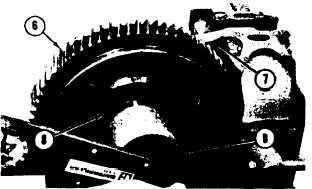

3. Put the cage in position in cover (7).

NOTE: Cover (7) is the cover from the transmis-

sion case that is over the studs for cage (4).

4. Install the nuts that hold the cover to the

cage. Put the cover in position in a vise.

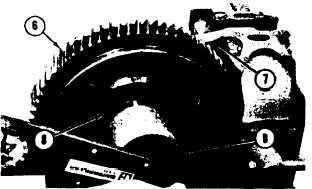

5. Install input gear (6) and bearing (8) on the

cape. Put 4S9416 Anti-Seize Compound on

the face and threads of the nut for the

bearing. Install the lock and the nut that

hold the bearing. Tighten the nut with tool

(B) to a torque of 170 + 15 lb. ft. (23.5 ±

2.1 mkg). Bend the tab of the lock into the

nut.

6. Remove the cage from the cover. Remove

the cover from the vise. Put the cage and

the input gear in position on three blocks as

shown.

7. Install the bearings in gears (11) and (13).

Install the gears and the thrust washers in

carrier (9). install shafts (10) and (12) in

the carrier and the bearings for the gears.

Install the pins that hold the shafts to the

carrier. Put carrier (9) in position on the

input gear. Install the retaining ring that

holds it to the input gear.

CAUTION: The pins that hold the shafts to the

carriers must be installed even with the outer

surface of the carrier. If they are installed further,

they will prevent oil flow for lubrication to the

gears. This is the same on all pins for carriers in this

transmission.

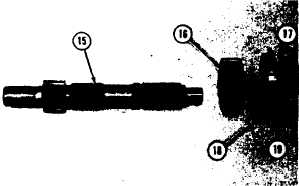

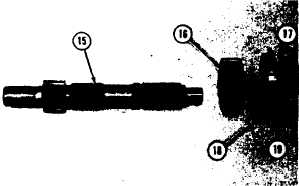

8. Install gear (16) on center shaft (15). Heat

bearing (18) in oil to a temperature of

275° F (135° C). lnstall the bearing on gear

2-98

DISASSEMBLY AND ASSEMBLY

(17) so the face of the bearing is even with

the face of the gear. Install ring (19) on the

bearing. Install the gear on the center shaft.