TM 5-3805-263-14P-3

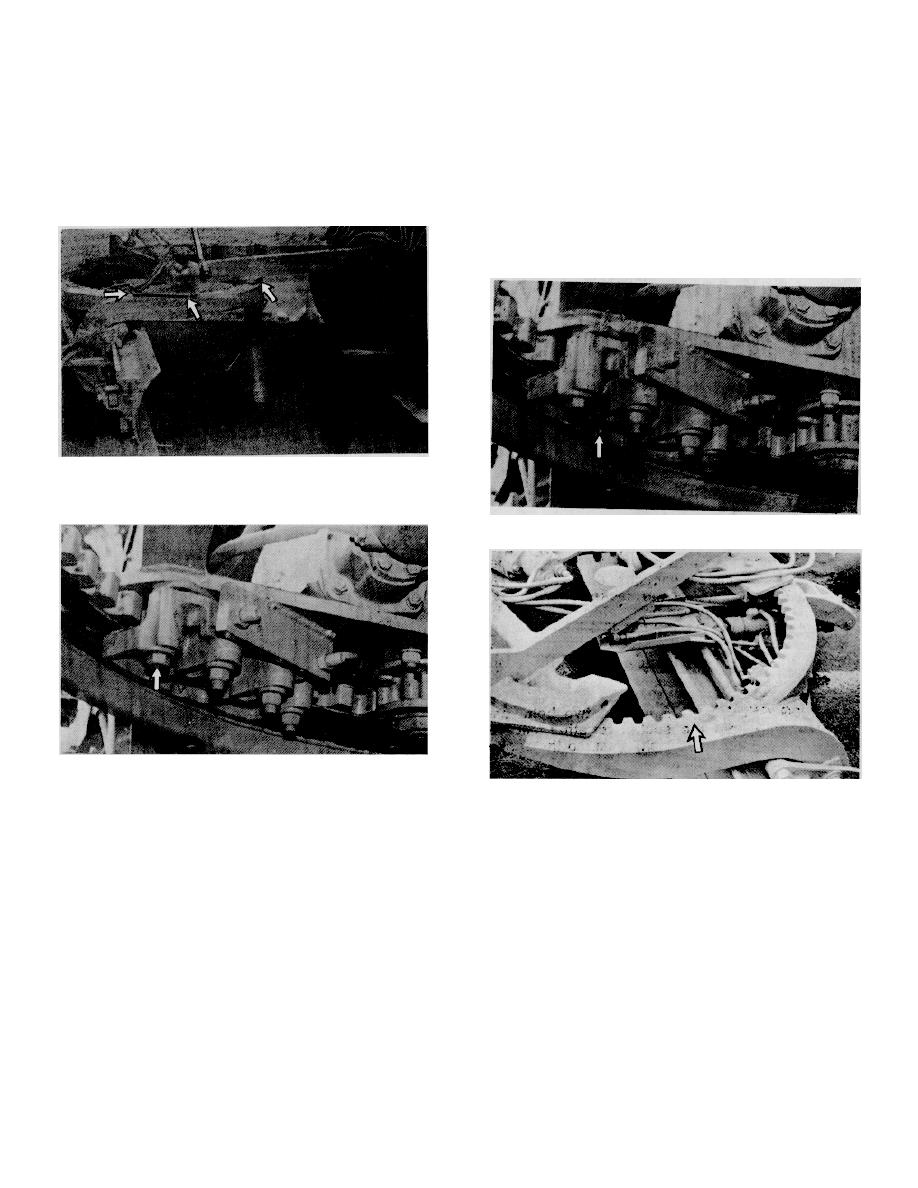

Blade Circle-Measure Circle to Shoe Clearance

1. With the machine level and blade 90 to the frame,

5. Measure the clearance between the top of the back

lower the blade to the ground and apply slight down

shoes(4 shoes) and the circle. Distance should be

pressure.

between 0.51 and t.3 mm (.020 and .090 inch). Adjust if

2. Support the front of the circle so that the circle is

necessary.

touching drawbar wear strips at a minimum of three

places around the circle.

Clearance should be measured at both ends of the shoe.

The smallest clearance dimension should be used to

determine the adjustment required.

Insufficient

clearance will prevent circle rotation.

3. Measure the thickness of all wear strips. Replace

all wear strips if any one is 1.5 mm (.06 inch) or less.

6. Lubricate the circle guide shoes. See "Circle Guide

Shoes" in the "Every 10 Service Hours or Daily" section.

4. Make sure the bolts holding the shoes to the

7. Clean the top of the circle. Be sure to remove all of

drawbar are tight.

the old lubricant. Apply lubricant to the top of the circle

and the inner vertical surface of circle, which the shoes

contact.

5-15