DISASSEMBLY AND ASSEMBLY

TM 5-3805-263-14&P-3

HYDRAULIC CYLINDERS

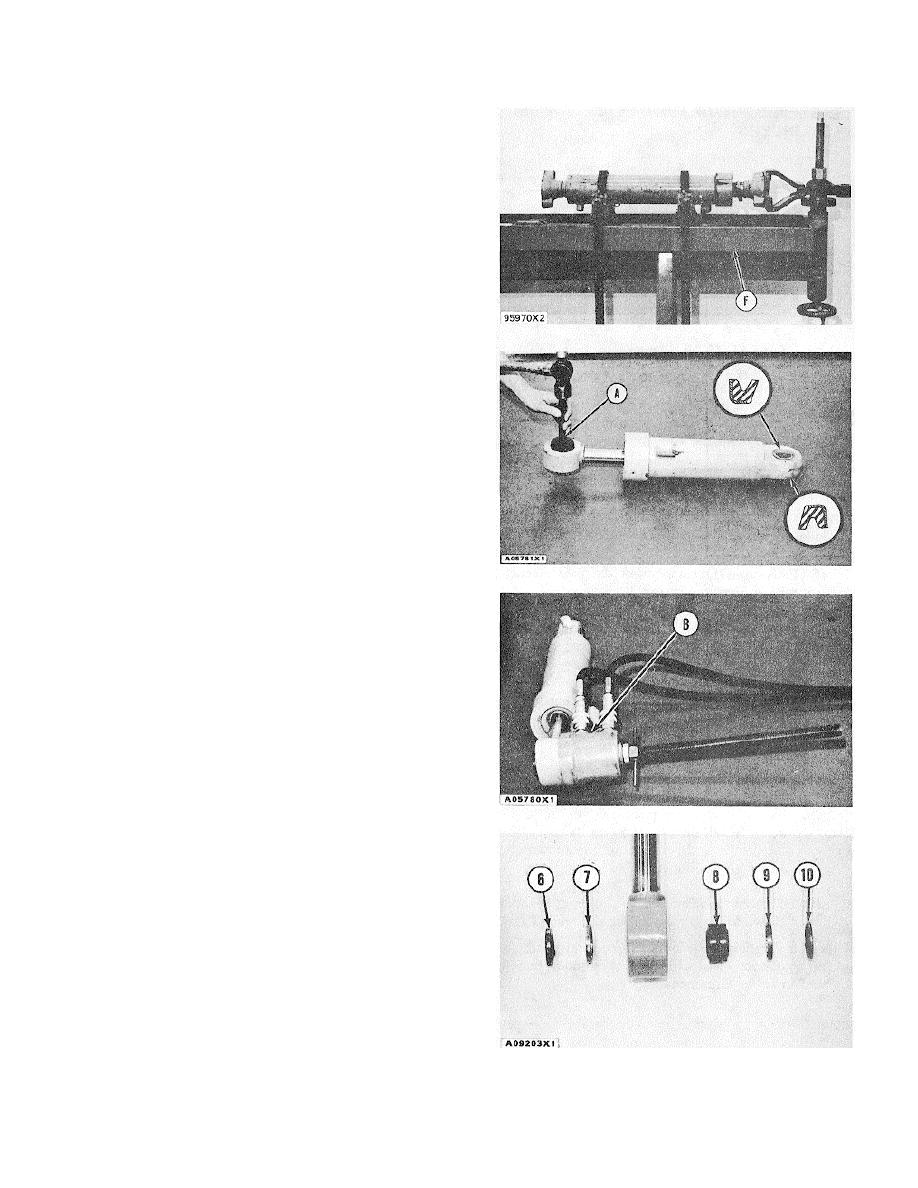

11. Fasten a hoist to the cylinder.

Remove the

cylinder from tooling (F).

12. Install the inlet and outlet tubes on the cylinder if

the cylinder is so equipped.

13. If the cylinder is equipped with seals and

bearings (non-metal), install a new seal in each

end of the cylinder with tooling (A). 14. Install

the seals with the lips even with and toward the

outside surface of the cylinder.

15. Install a new bearing (non-metal) in each end of

the cylinder with tooling (B).

16. Install the bearing so it just makes contact with

the seal.

CAUTION

Tooling (B) must be used to install

the bearings to prevent damage.

17. Install another seal in each end of the cylinder in

the same manner outlined in Steps 13 and 14.

18. If the cylinder is equipped with seals, rings and

bearings (metal), install ring (7) and seal (6) with

tooling (A). Install bearing (8) in the cylinder.

Install ring (9) and seal (10) with tooling (A).

CAUTION

Install the seals with the lips in the

same direction that the pin is

installed in to prevent dam age to the

lips.

end by:

a) install steering, wheel lean, blade lift, blade

centershift, blade sideshift, blade tip, or

articulation cylinder

3-270