TM 5-3805-263-14&P-3

SPECIFICATIONS

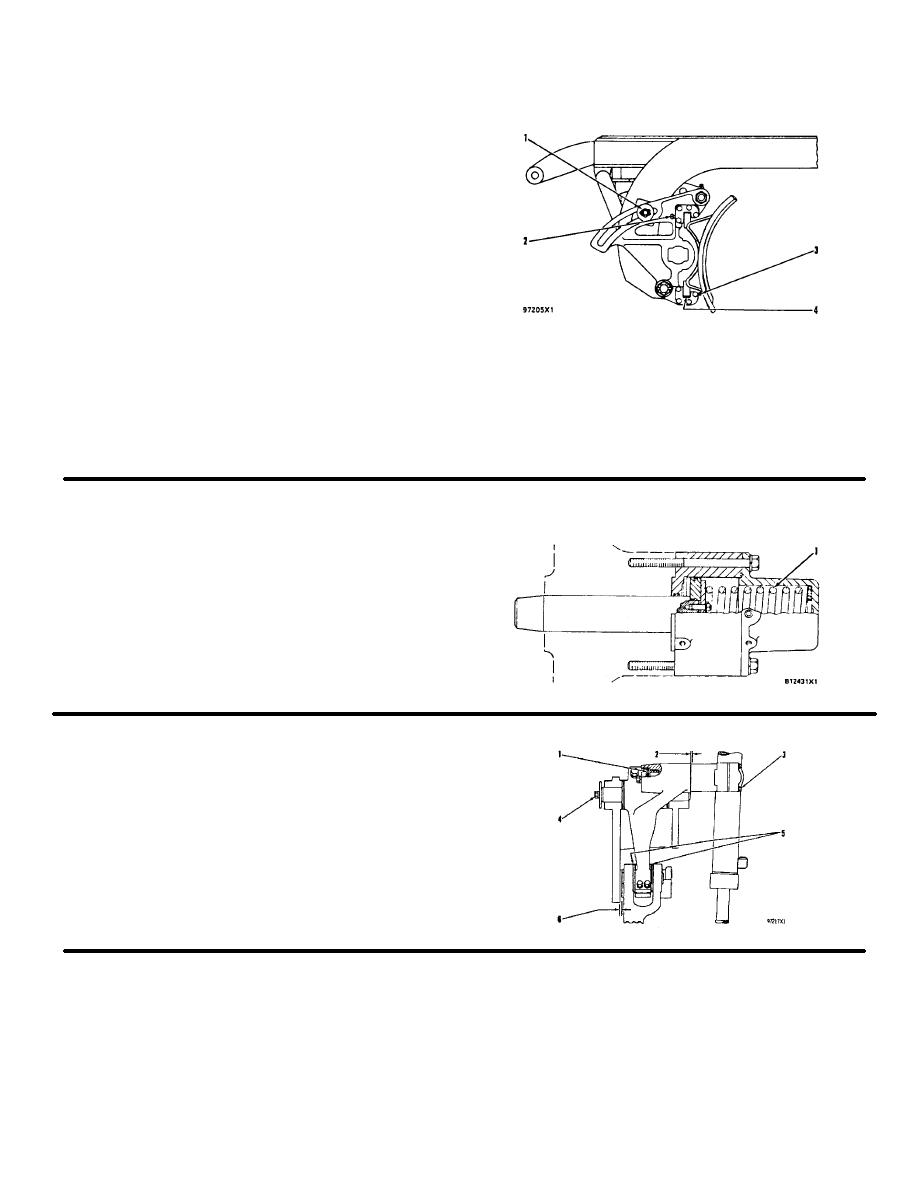

BLADE TIP

Blade Group

(2G6059)

(1) Nut must not be tight Bracket must slide on beam.

(2) Setscrew (six and two).

(3) Setscrew (six).

Adjustment procedure:

Step 1: Lift blade off ground, but do not support the

blade.

Step 2 Turn setscrews clockwise until there is no

free play with

the blade.

Step 3: Loosen setscrews (counterclockwise), '4

turn (90').

NOTE: Setscrews (2) and (3) will not turn (after the

adjustment made) when 9S3263 Thread Lock is

used on the setscrews.

(4) Shims under wear plate. Use shims as needed to

get

clearance between rail and wear plate,

clearance ................ .005 to .035 in. (0.13 to 0.89 mm

CENTERSHIFT LOCK

(8D9920)

(1) 10D4753 Spring

Length under test force .......................... 6 In (152 mm

Test force ...............................286 + 17 lb (1275 + 761

Free length after test .......................8.75 in (222.3 mm

Outside diameter .............................3.625 in (92 1 mm

CENTERSHIFT AND BLADE LIFT

(8D5285)

(1) Shims, use as needed to get end clearance

(2) End clearance (maximum) .........010 in (0 25 mm

(3) Torque for bolts in

yoke clamp ....................95 + 5 lb ft (130 + 7 N-m

(4) Torque for bolt ................95 - 5 lb ft (130 + 7 N-m

(5) Shims use as needed to get clearance between pin

and frame

(6) Clearance between pin and

frame ........................ 09 + 03 in (2.25 + 0 76 mm

3-108