TM 5-3805-263-14&P-3

HYDRAULIC SYSTEM

With the passages in the valves together, only one line

AND STEERING

for the pump oil (2) and one line for the return oil (3) is

(14) is the same as the pressure of the oil in line (10).

needed for all of the implement valves in a control valve.

When more force is needed to lower the blade, there is

an increase in the pressure of the pump oil to the head

Implement Valve

end of cylinder (4). When the pressure of the pump oil

The operation of each implement valve is the same.

goes to 1500 psi (103.5 kg/cm2), the oil in line (14)

There is a difference in each implement valve. The rate

moves the shuttle valve in the pump and the oil pressure

of oil flow (gpm, litre/min) from the outlets of each valve,

from the pump can go to approximately 3500 psi (246.1

to the implement, is not the same. The rate of oil flow

kg/cm2 ).

from each opening in an implement valve, for a hydraulic

cylinder, is not the same. There are implement valves

that have approximately the same rate of oil flow from

each opening. The size of the orifices from valve spool

(2), to openings (4) and (5), is one of the controls for the

rate of flow. The other control is the force of spring (14)

against valve (9). The spring force is not the same in

each implement valve.

Resolver valve (7) lets the oil with the higher pressure in

either the passage to opening (4), or the passage to

opening (5), go through the valve into passage (8). The

IMPLEMENT CONTROLS

higher pressure of the oil on the ball in valve (7) closes

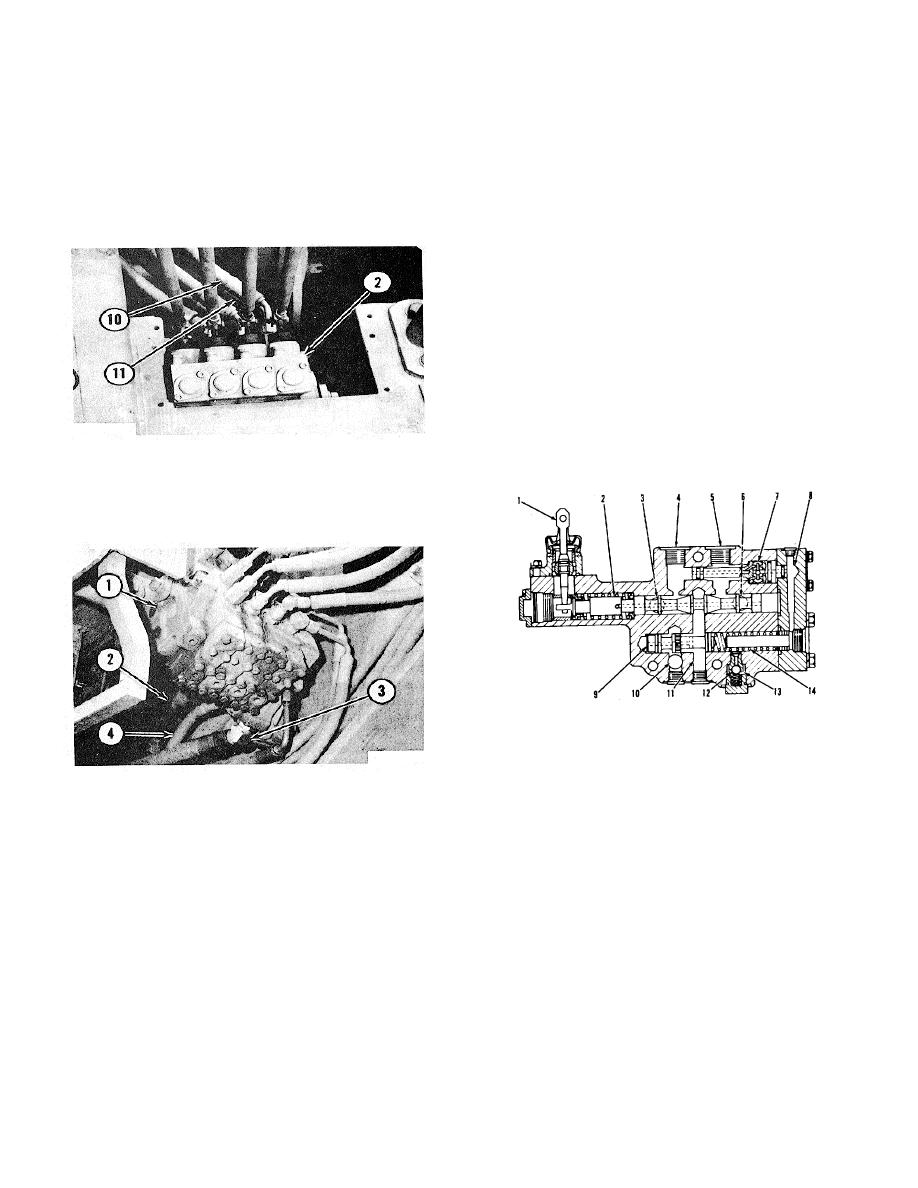

2. Implement valve to raise or lower the blade (right

the valve passage with oil

side). 10. Line from implement valve to head of

cylinder. 11. Line from implement valve to rod end of

cylinder.

CONTROL VALVE FOR IMPLEMENTS

IMPLEMENT VALVE FOR A CYLINDER

1. Lever. 2. Valve spool. 3. Passage to tank. 4.

Opening for head end of a cylinder. 5. Opening for rod

end of a cylinder. 6. Passage to tank. 7. Resolver

CONTROL VALVE

valve. 8. Passage. 9. Valve for control of oil flow. 10.

1. Implement valves (four). 2. Line for pump oil. 3.

Passage from pump. 11. Passage. 12. Check valve.

Line for return oil. 4. Oil line to shuttle valve in variable

13. Passage for oil to shuttle valve in pump. 14. Spring.

displacement pump.

Each of the control valves for the implements, on each

side of the console for the control levers and steering

wheel, has 'four to five implement valves.

The

implement valves (1) are side by side and each valve is

approximately 1.5 in. (38.1 mm) thick. The passages for

the pump oil in each implement valve are together and

the passages for the

3-15