TM 5-3805-261-34

HYDRAULIC SYSTEM MAINTENANCE. (cont)

10-13.

Power Blade and Blade Tip Check and Relief Valve

ASSEMBLY

PRESSURE

PART NO.

THICKNESS

CHANGE

6J8696

0. 048 INCH

670 PSI

5J6153

0. 007 INCH

95 PSI

3K6116

0. 031 INCH

430 PSI

1.

Install washer (16), spring (15),

shim(s) (14, Figure 10-113) and

valve (13) in body (17). Use

washer (16) and shim(s) (14) as

required to obtain a relief valve

setting of 4000 psi at a flow

rate of 2. 5 gallons per minute.

Refer to chart.

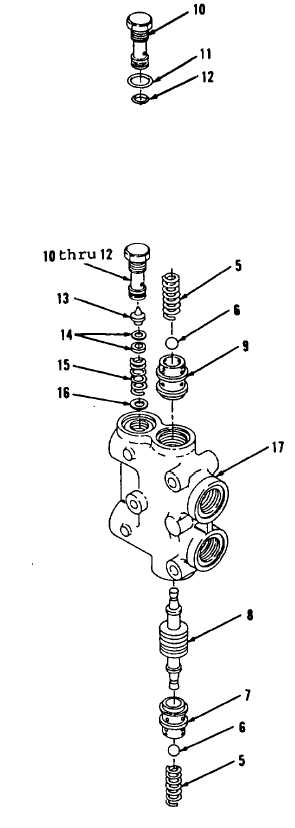

2.

Install new preformed packings

(12 and 11) on plug (10, Figure

10-114).

3.

Lubricate outer diameter of new

preformed packings (12 and 11)

with clean lubricating oil.

4.

Install items 12 thru 10 as an

assembly.

5.

Using dry ice or freezer, reduce

temperature of seat (9) and

install using alignment punch and

hammer until seated against

counterbore in body (17).

6

Position piston (8) in seat (9)

in body (17).

7.

Using dry ice or freezer, reduce

temperature of seat (7) and

install using alignment punch and

hammer until seated against

counterbore in body (17). Check

for full movement of piston (8)

travel through seats (9 and 7).

Figure 10-114.

Figure 10-113.

Go to Sheet 5

10-78