TM 5-3805-261-23-2

ROCKER ARM ASSEMBLY MAINTENANCE - CONTINUED

0273 00

ADJUSTMENT - CONTINUED

NOTE

Number one cylinder must be at compression stroke for proper valve adjustment.

6.

Check number one cylinder for compression stroke. Intake and exhaust valves must be closed. This can be checked by

visually inspecting the valves and by movement in both rocker arms. If exhaust valve is open, remove 3/8-16NC bolt

and turn engine 360 degrees.

7.

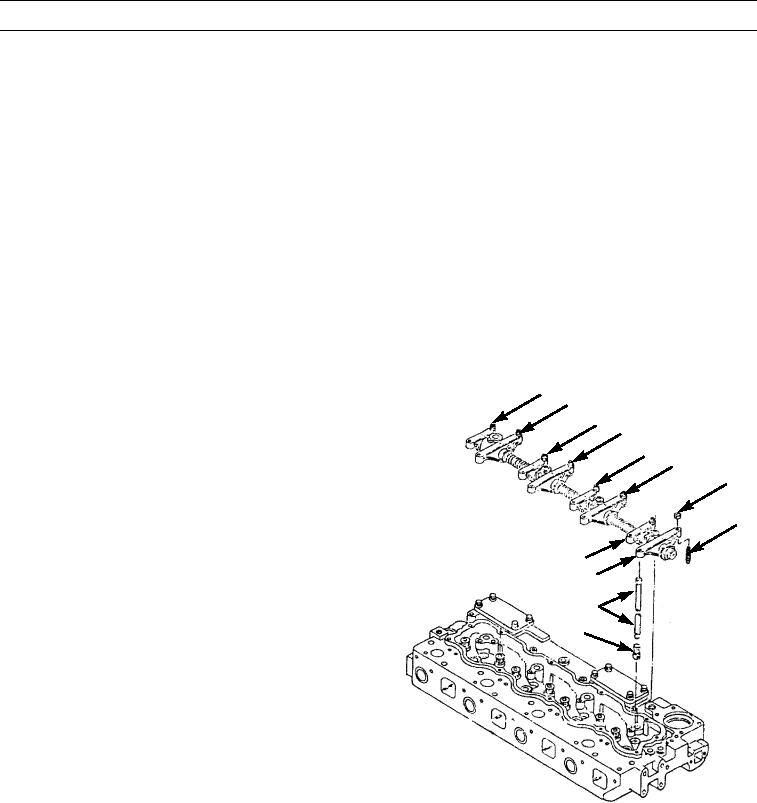

Adjust intake valves for cylinders 1 and 2. Turn adjusting screws (13) in arms (18 and 29) until a clearance of 0.012 to

0.018 in. (0.30 to 0.46 mm) is obtained. Secure screws (13) with nuts (8).

8.

Adjust exhaust valves for cylinders 1 and 3. Turn adjusting screws (13) in arms (14 and 34) until a clearance of 0.022 to

0.028 in. (0.56 to 0.71 mm) is obtained between arms (14 and 34) and push rods (6). Secure screws (13) with nuts (8).

NOTE

Remove 3/8-16NC bolt from flywheel before turning engine.

9.

Turn engine counterclockwise 360 degrees. Verify

56

51

that number 4 cylinder is at TC position.

37

10.

Install 3/8-16NC bolt in flywheel.

34

29

11.

Adjust intake valves for cylinders 3 and 4 by turning

25

screws in arms (37 and 56). Repeat adjustment proce-

8

dures in step 7.

12.

Adjust exhaust valves for cylinders 2 and 4 by turning

13

screws in arms (25 and 51). Repeat adjustment proce-

dures in step 8.

18

13.

Tighten eight nuts (8). Hold adjusting screws and

14

tighten eight nuts to 22 lb-ft (30 Nm).

6

5

397-1322

14.

Remove engine turning gear.

15.

Remove 3/8-16NC bolt from flywheel housing.

16.

Install valve cover (WP 0031 00).

END OF WORK PACKAGE

0273 00-9/(-10 Blank)