FUEL SYSTEM

TESTING AND ADJUSTING

TM 5-3805-263-14&P-2

temperature at an exhaust manifold port is an indica-

tion of no fuel to the cylinder. This can possibly be an

indication of a nozzle with a defect. Extra high tem-

perature at an exhaust manifold port can be an indi-

cation of too much fuel to the cylinder, alsocaused by

a nozzle with a defect.

The most common defects found with the fuel

injection nozzles are:

1. Carbon on tip of the nozzle or in the nozzle

orifice.

2. Orifice wear.

CAUTION

Do not teat nozzles unless you have the correct

service tools.

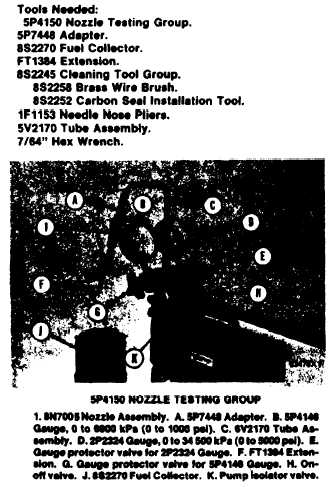

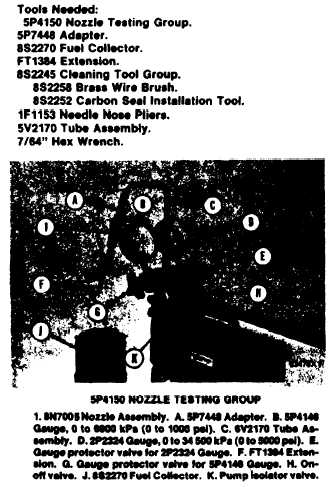

TESTING 8N7005 FUEL

INJECTION NOZZLES

1-38

CAUTION

Be sure to use clean SAE J967 Calibration oil

when tests are made. Dirty test oil will damage

components of fuel injection nozzles. The term-

perature of the test oil must be 18 to 24°C (88 to

75°F) for good test results.

The 8N7005 Fuel Injection Nozzle can not be

disassembled for cleaning or adjustment. Do the tests

that follow to determine if the nozzle performance is

acceptable.

1. Valve Opening Pressure Test.

II. Flush the Nozzle.

III. Tip Leakage Test.

IV. Orifice Restriction Test.

V. Bleedscrew Leakage Test.

Nozzle Preparation for Test

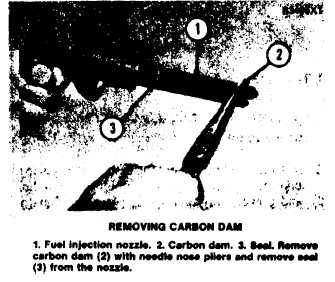

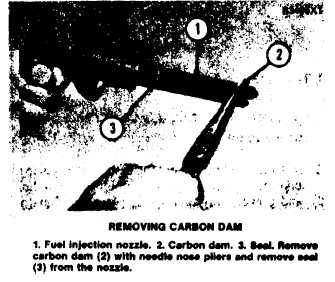

Before fuel injection nozzle (1) can be tested, all

loose carbon around the tip of the nozzle must be

removed with the 8S2258 Brass Wire Brush (M).