TM 5-3805-263-14&P-3

Every 10 Service Hours or Daily

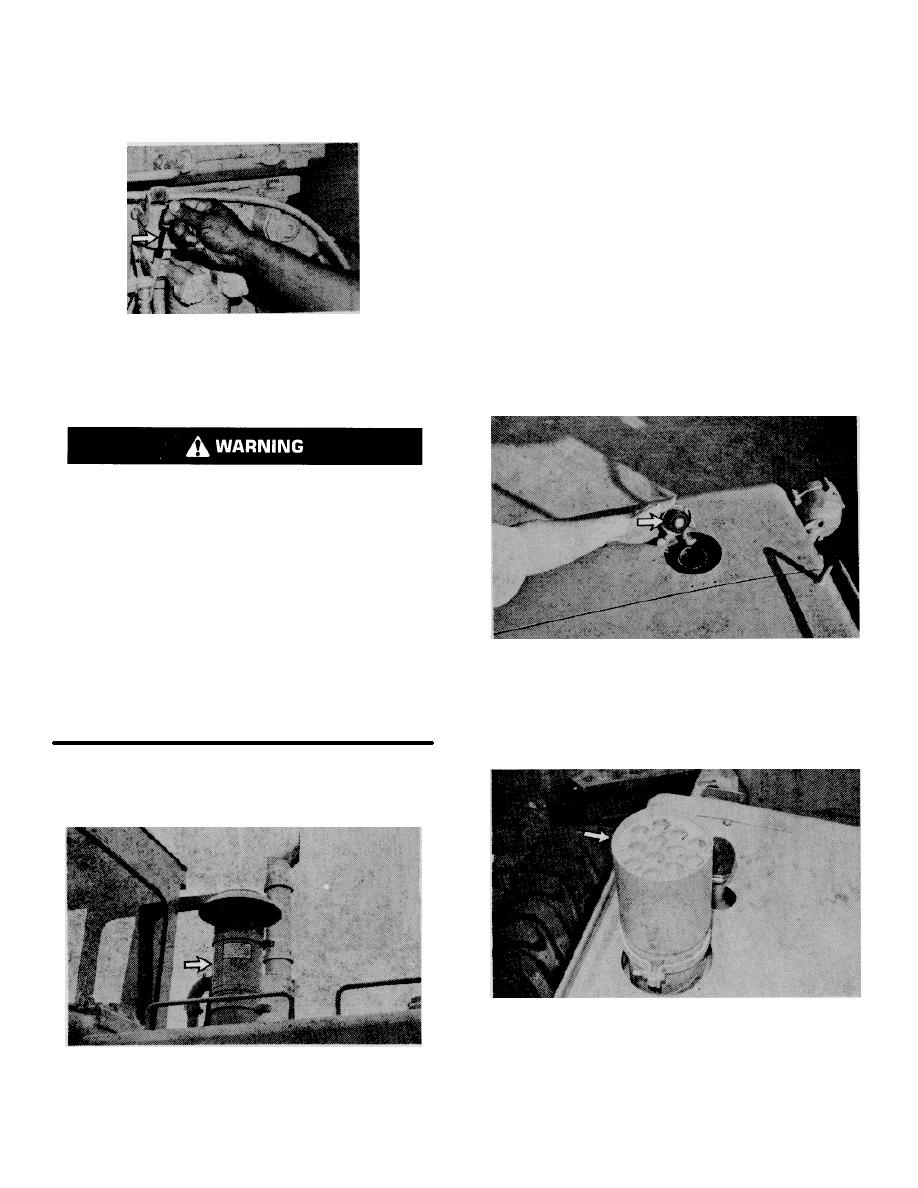

(1) Engine Crankcase

2. ENGINE RUNNING: at low idle.

Keep the oil level above the ADD mark and on or below

the FULL mark on the dipstick.

ENGINE STOPPED: Maintain the oil level between the

ADD and FULL marks on the ENGINE STOPPED side of

the dipstick.

The machine must be level, equipment lowered and the

3. Add oil if necessary.

parking brake applied.

1. Measure the oil level.

(2) Radiator

At Operating Temperature, engine

coolant is hot and under pressure.

Steam can cause personal injury.

Check coolant level ONLY when

engine is stopped and radiator cap is

cool enough to touch with your hand.

Remove filler cap slowly to relieve

1. Remove the radiator cap slowly to relieve pressure.

pressure.

Observe coolant level. Inspect the cap gasket and

replace it if necessary.

Cooling System Conditioner contains

alkali. Avoid contact with skin and

2. Inspect the coolant level with the engine stopped and

eyes to prevent personal injury.

cold. Maintain the coolant level within 1 cm (1/2 inch)

below the top of fill pipe.

If it is necessary to add coolant daily, inspect cooling

system for leaks.

(3) Precleaner

2. Remove precleaner, if necessary, and clean.

1. Inspect precleaner for accumulation of dirt or debris.

5-32