TM 5-3805-263-14&P-3

DISASSEMBLY AND ASSEMBLY

HYDRAULIC PUMP

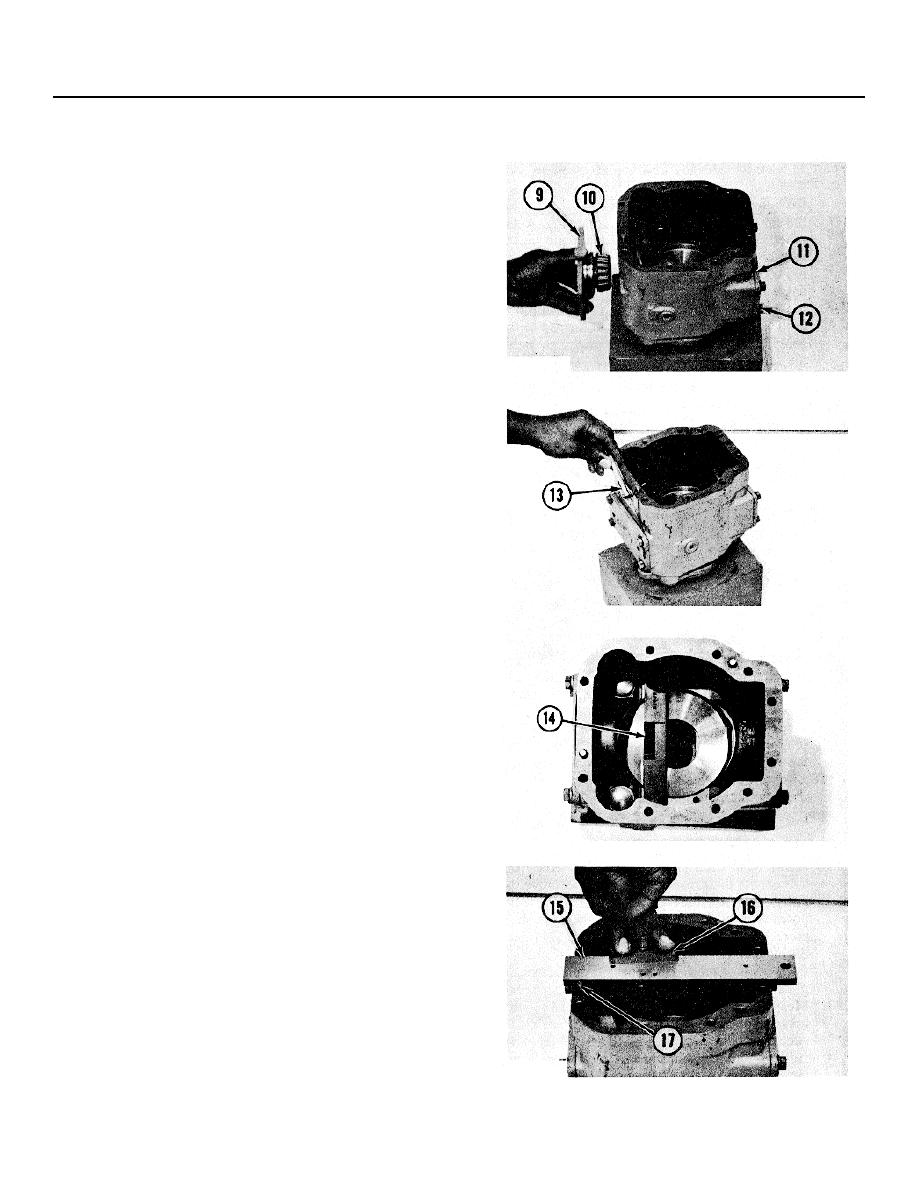

7. Heat bearing cones (10) to a maximum

temperature of 275F (135C). Install the bearing

cones on covers (9) and (11).

8. Install the O-ring seal on cover (11). Put cover

(11) in position in the pump body and the

swashplate with .015 in. (0.38 mm) shims. Tighten

bolts (12) that hold cover (11) to the pump body to

a torque of 32 lb. ft. (43 Nm).

9. Install cover (9) in the pump body and the

swashplate. Install the bolts that hold it. Tighten

the bolts evenly in 10 Ib. in. (1.1 Nm) steps until

the bolts have a torque of 40 lb. in. (4.5 Nm).

Tighten the bolts in a clockwise direction while the

swashplate is moved backward and forward.

10. Measure gap between cover (9) and pump body

with feeler gauge (13) at the four bolt locations.

Install shims that are the same thickness as the

average gap measured plus .008 in. (0.20 mm).

NOTE: If the thickness of shims is less than .005 in.

(0.13 mm) or more than .025 in. (0.64 mm), add the

thickness of the shims for cover (9) to the thickness of

the shims for the other cover. Divide the total thickness

of the shims evenly and install the same thickness of

shims on each cover.

11. Install the shims and the O-ring seal on cover (9).

Install the cover on the pump body. Tighten the

bolts that hold the cover to a torque of 32 Ib. ft. (43

Nm). Make sure the swashplate is free to move.

12. Install stop angle bar (14) from tooling (D) on the

swashplate.

NOTE: The stop angle bar must be installed with the

deepest point of the two angles toward the minimum stop

bolt. The bar must be at a 90 angle to a line through the

center of the bearings.

13. Put gauging bar (15) from tooling (D) on the body

with the end of the gauging bar against dowel (17).

NOTE: The gauging bar must be parallel with a line

through the center of the bearings.

14. Install depth gauge (16) from tooling (D) in one of

the holes in the gauging bar that is directly over the

deepest angle on the stop angle bar.

3-246