TM 5380-263-14&P-3

VEHICLE SYSTEMS

WHEEL SPINDLES

INSTALL WHEEL SPINDLES

Tools Needed

A

5S4276

Seal Installer

1

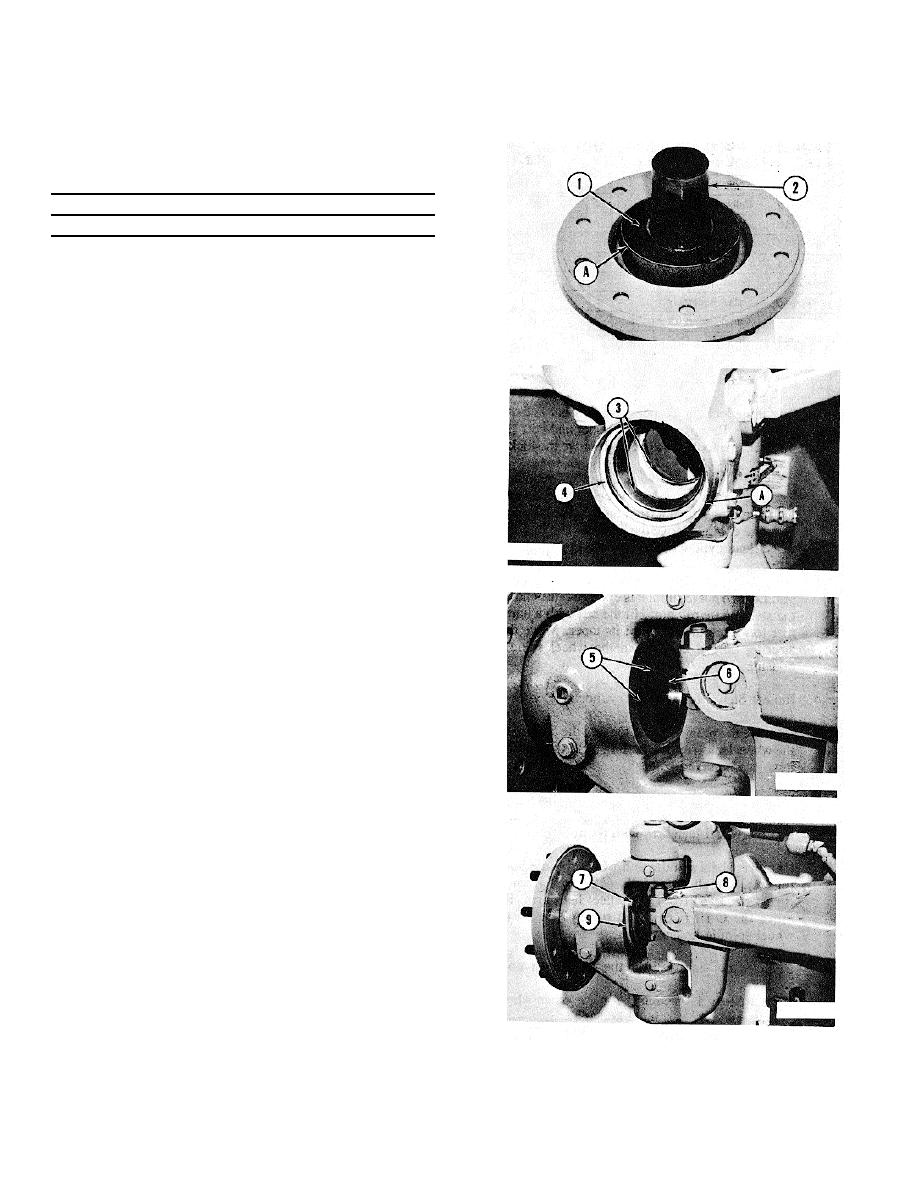

1. Heat bearing (1) to a temperature of 275F

(1350C). Install bearing (1) on wheel spindle (2).

2. Make sure the Duo-Cone seals are clean and dry.

Make sure all the metal surfaces that the seals

make contact with are clean and dry. In-stall the

Duo-Cone seal in the wheel spindle with tooling

(A).

3. Lower the temperature of bearing cups (3). Install

the bearing cups in the wheel spindle housing.

4. Install Duo-Cone seal (4) in the wheel spindle

housing with tooling (A). Put a small amount of oil

on the metal surfaces of both seals that make

contact with each other.

5. Heat the inner bearing to a maximum tempera-ture

of 2750F (1350C). Fasten a hoist to the wheel

spindle housing. Install the inner bearing on wheel

spindle. Install spindle in housing.

6. Install retainer (6) and bolts (5) that hold the

retainer to the wheel spindle. Tighten the bolts to a

torque of 95 + 5 Ib.ft. (130 + 7 N.m).

7. Install a new O-ring seal on cover (9). Put the

cover in position on the wheel spindle housing.

Install bolts (7) that hold it.

8. Tighten bolt (8) to a torque of 515 + 20 lb.ft. (700

+ 25 N.m). Fill the wheel spindle housing with oil to

its correct level.

end by:

a) install front wheels

3-177